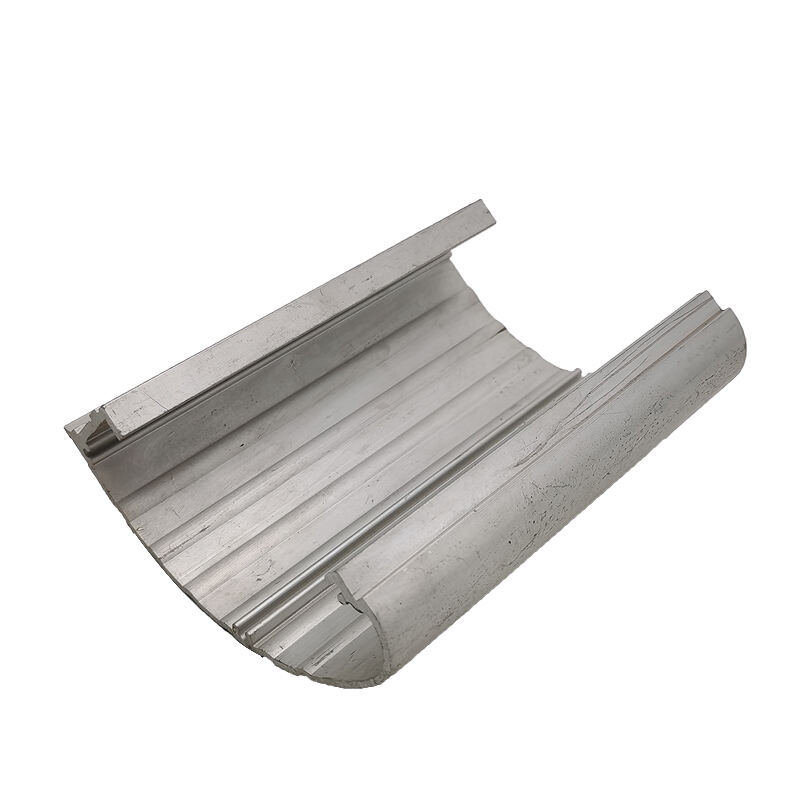

aluminum extrusion

Aluminum extrusion is a sophisticated manufacturing process that transforms aluminum alloy into custom-shaped profiles by forcing heated material through a die. This versatile technique creates complex cross-sectional shapes that maintain consistent dimensions throughout their length. The process begins with heating aluminum billets to temperatures between 800-925°F, making the metal malleable yet still solid. The heated aluminum is then pushed through a precision-engineered die using hydraulic pressure, emerging as a perfectly formed profile that cools and hardens. Modern aluminum extrusion technology enables the production of both standard and custom profiles, offering unlimited design possibilities for various industries. The process excels in creating components with intricate internal channels, multiple hollow sections, and precise dimensional tolerances. These profiles can be manufactured in lengths up to 100 feet, though typical commercial lengths range from 12 to 30 feet. The versatility of aluminum extrusion makes it ideal for applications in construction, automotive, aerospace, electronics, and renewable energy sectors, providing lightweight, durable, and cost-effective solutions for complex engineering challenges.