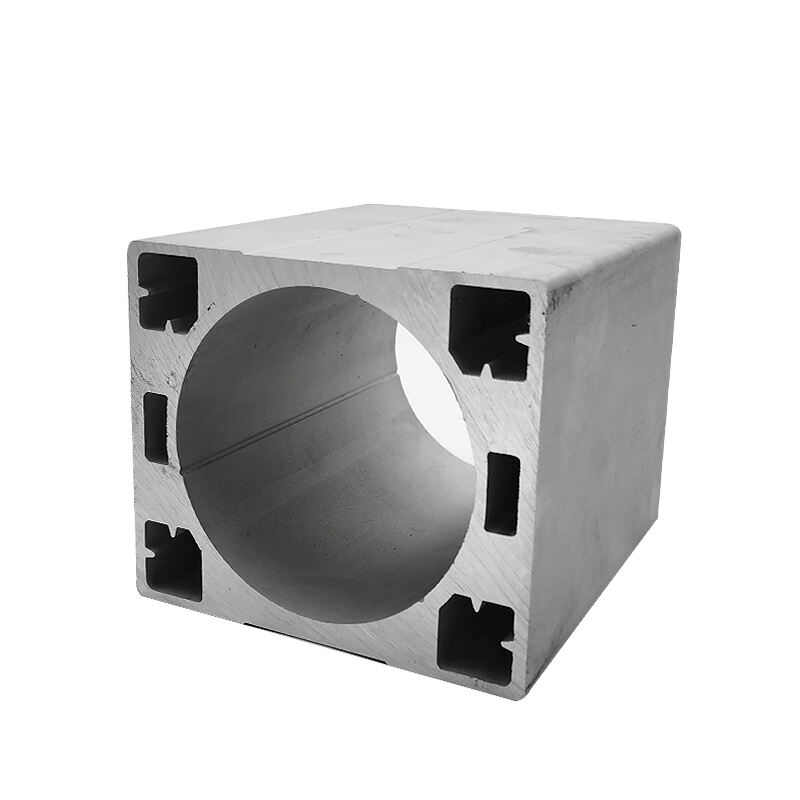

anodized aluminum profile

Anodized aluminum profiles represent a sophisticated advancement in metal processing technology, combining durability with aesthetic appeal. This specialized manufacturing process creates a protective oxide layer on the aluminum surface, significantly enhancing its natural properties. The electrochemical process involves immersing aluminum profiles in an acid electrolyte bath while applying an electric current, resulting in a controlled oxidation that forms a highly durable, corrosion-resistant surface. The anodized layer, typically ranging from 10 to 25 micrometers in thickness, becomes an integral part of the metal rather than just a surface coating. These profiles excel in both indoor and outdoor applications, offering exceptional weather resistance and maintaining their appearance over extended periods. The anodizing process allows for various color options through electrolytic coloring or organic dye absorption, providing design flexibility while maintaining the metal's natural metallic luster. In terms of functionality, anodized aluminum profiles demonstrate superior hardness, enhanced wear resistance, and excellent electrical insulation properties. They find extensive applications in architectural frameworks, industrial equipment, consumer electronics, and transportation systems, where their combination of lightweight structure and robust performance proves invaluable.