aluminium extrusion products

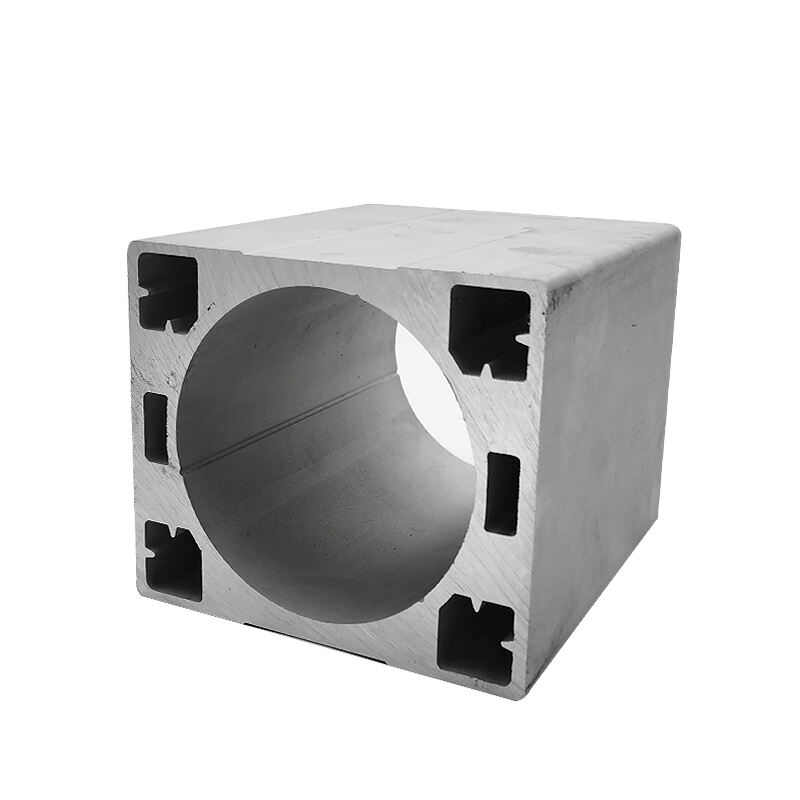

Aluminum extrusion products represent a cornerstone of modern manufacturing, offering versatile solutions across numerous industries. These products are created through a sophisticated process where aluminum billets are heated and forced through specially designed dies to create precise cross-sectional profiles. The resulting products combine lightweight durability with exceptional strength, making them ideal for various applications. The process allows for intricate designs and complex geometries while maintaining structural integrity. These extruded products feature excellent thermal conductivity, corrosion resistance, and recyclability, making them environmentally sustainable choices. In industrial applications, they serve as crucial components in manufacturing equipment, construction frameworks, and transportation systems. The technological features include customizable surface finishes, tight tolerance capabilities, and the ability to incorporate multiple functionalities within a single profile. Their applications span across automotive components, building facades, electronics housing, solar panel frames, and aerospace structures. The precision engineering involved ensures consistent quality and dimensional accuracy, while the flexibility of the extrusion process enables cost-effective production of both standard and custom profiles. Modern aluminum extrusion technology also accommodates various alloy compositions, allowing manufacturers to optimize material properties for specific applications, from high-strength structural components to decorative architectural elements.