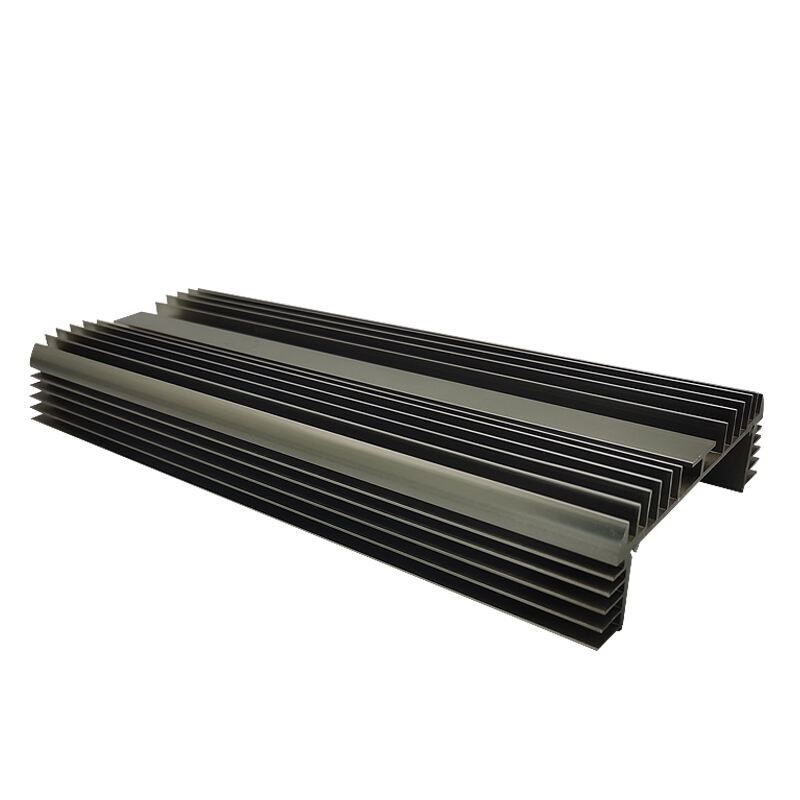

extruded aluminium sections

Extruded aluminium sections represent a cornerstone in modern manufacturing and construction, offering versatile solutions through a sophisticated production process. These sections are created by pushing heated aluminum through specially designed dies, resulting in precise profiles that maintain consistent cross-sectional dimensions throughout their length. The process allows for remarkable design flexibility, enabling the creation of complex shapes and profiles that would be impossible or cost-prohibitive to achieve through traditional manufacturing methods. These sections excel in structural applications due to their exceptional strength-to-weight ratio, making them ideal for both architectural and industrial uses. The material's inherent characteristics, including corrosion resistance and thermal conductivity, are enhanced through the extrusion process. Modern extrusion technology enables the production of sections with intricate internal channels, perfect for heat dissipation applications, and complex joint designs that facilitate easy assembly. These sections can be further customized through various surface treatments, including anodizing and powder coating, to meet specific aesthetic and functional requirements. The versatility of extruded aluminium sections extends to their application in industries ranging from construction and automotive to electronics and renewable energy, where their combination of lightweight properties and structural integrity proves invaluable.