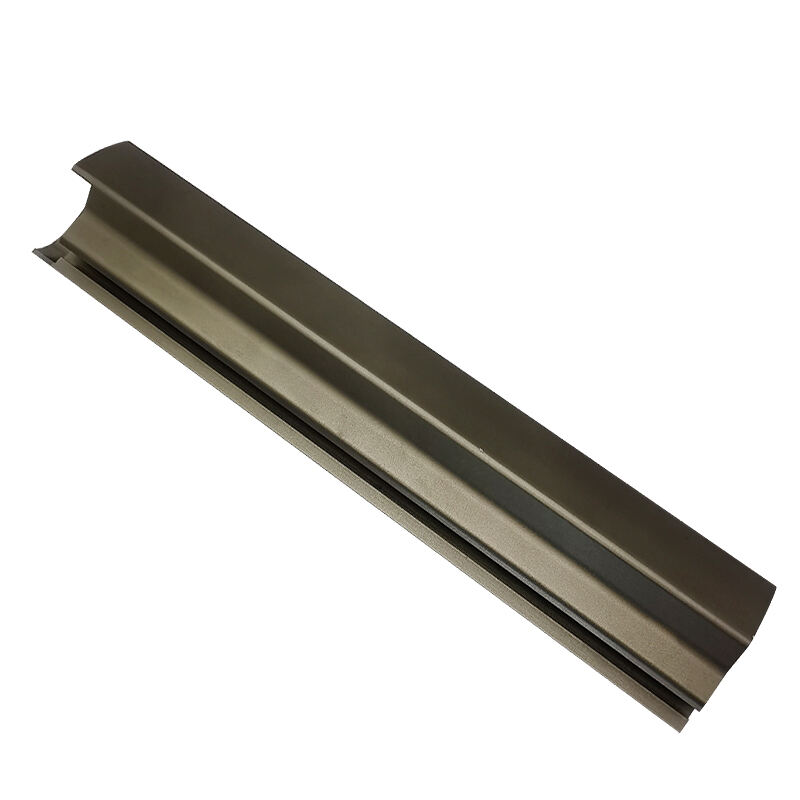

structural aluminum extrusions

Structural aluminum extrusions represent a sophisticated manufacturing process that transforms aluminum alloy into precisely designed profiles for various industrial and architectural applications. This versatile material solution combines lightweight properties with remarkable strength, making it ideal for modern construction and engineering projects. The process involves pushing heated aluminum through a die to create complex cross-sectional profiles that maintain consistent dimensions throughout their length. These extrusions offer exceptional design flexibility, allowing for intricate shapes that would be difficult or impossible to achieve through traditional manufacturing methods. The resulting profiles feature integrated fastening points, structural support elements, and functional details that significantly reduce assembly time and costs. In industrial applications, structural aluminum extrusions serve as the backbone for equipment frames, conveyor systems, and modular manufacturing solutions. In architecture, they form the foundation for curtain walls, window frames, and structural supports, providing both aesthetic appeal and functional performance. The material's inherent corrosion resistance and durability ensure long-term reliability in various environmental conditions, while its high strength-to-weight ratio makes it particularly valuable in transportation and aerospace applications where weight reduction is crucial.