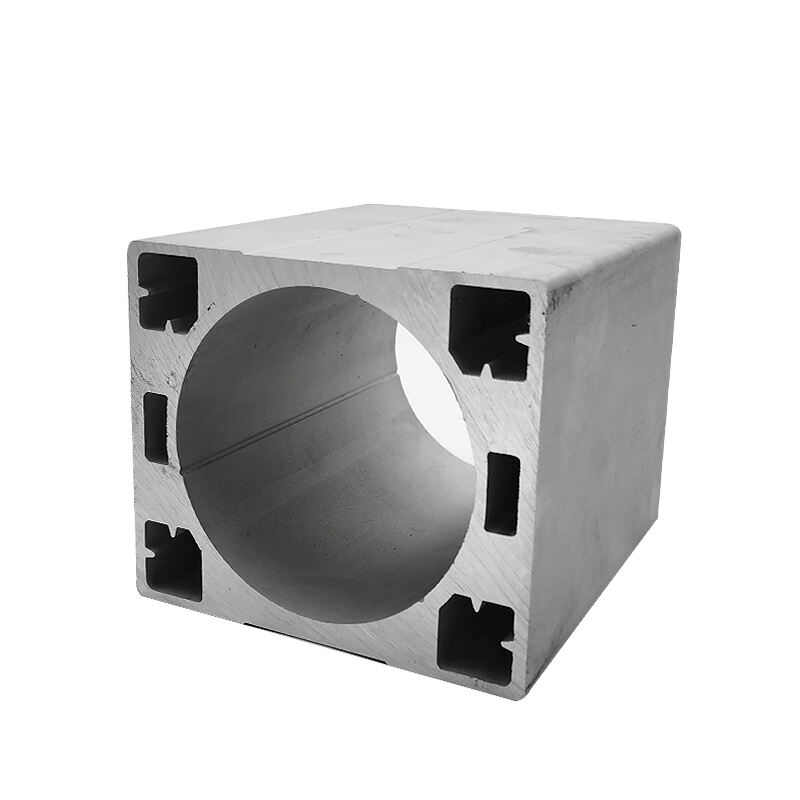

aluminium extrusion box

The aluminium extrusion box represents a versatile industrial solution that combines durability, functionality, and aesthetic appeal. This precisely engineered enclosure is manufactured through an advanced extrusion process, where aluminum is forced through a die to create seamless, uniform profiles that form the box structure. These boxes feature exceptional structural integrity while maintaining a lightweight composition, making them ideal for various applications across multiple industries. The design incorporates specialized heat dissipation properties, crucial for housing electronic components and sensitive equipment. With customizable dimensions and configurations, these boxes can be tailored to meet specific requirements, whether for small-scale electronic projects or large industrial applications. The surface treatment options, including anodizing and powder coating, provide enhanced corrosion resistance and aesthetic versatility. These boxes typically include integrated mounting features, cable management systems, and modular compatibility, allowing for easy installation and maintenance. The manufacturing process ensures precise tolerances and consistent quality, resulting in a product that meets international standards for industrial enclosures. Modern aluminium extrusion boxes often incorporate EMI shielding capabilities, making them suitable for sensitive electronic applications where electromagnetic interference protection is crucial.