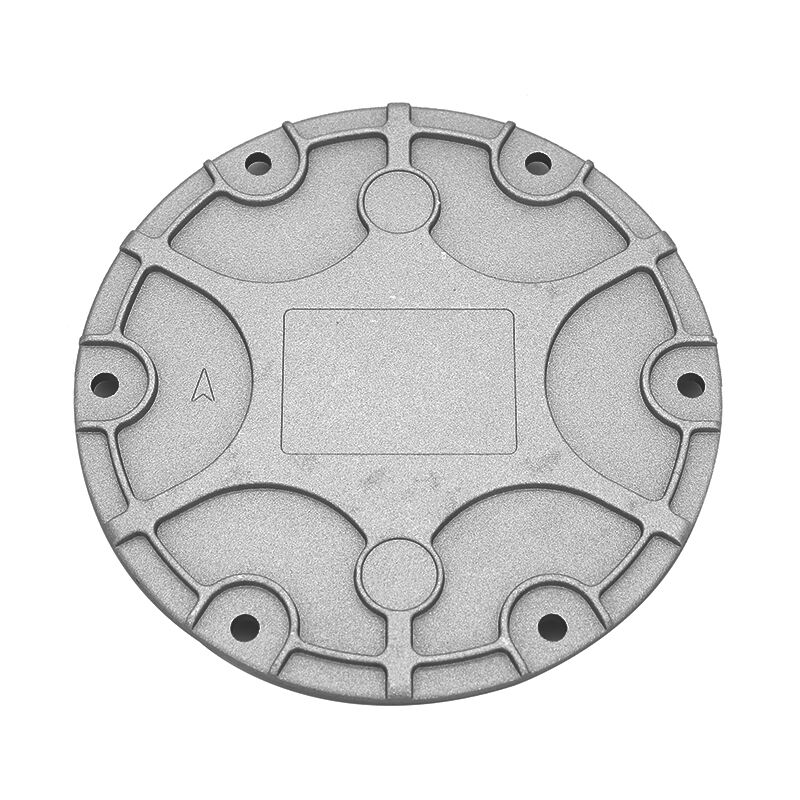

aluminium pressure die casting

Aluminium pressure die casting is a sophisticated manufacturing process that transforms molten aluminum into precisely engineered components through high-pressure injection into reusable metal dies. This advanced manufacturing method combines speed, accuracy, and cost-effectiveness to produce complex parts with exceptional surface finish and dimensional stability. The process begins with melting aluminum alloy to specific temperatures, followed by forcing the molten metal into a steel mold cavity under high pressure, typically between 10 and 120 MPa. This pressure maintains until the metal solidifies, ensuring complete cavity filling and minimal porosity. The technology allows for the production of intricate geometries with thin walls, detailed features, and tight tolerances that would be difficult or impossible to achieve through other manufacturing methods. Modern aluminum pressure die casting incorporates advanced features such as vacuum assistance, real-time monitoring systems, and automated extraction processes to ensure consistent quality. The applications span across numerous industries, including automotive components, electronics housings, aerospace parts, and consumer goods. The process is particularly valuable for high-volume production runs where consistency and reliability are paramount.