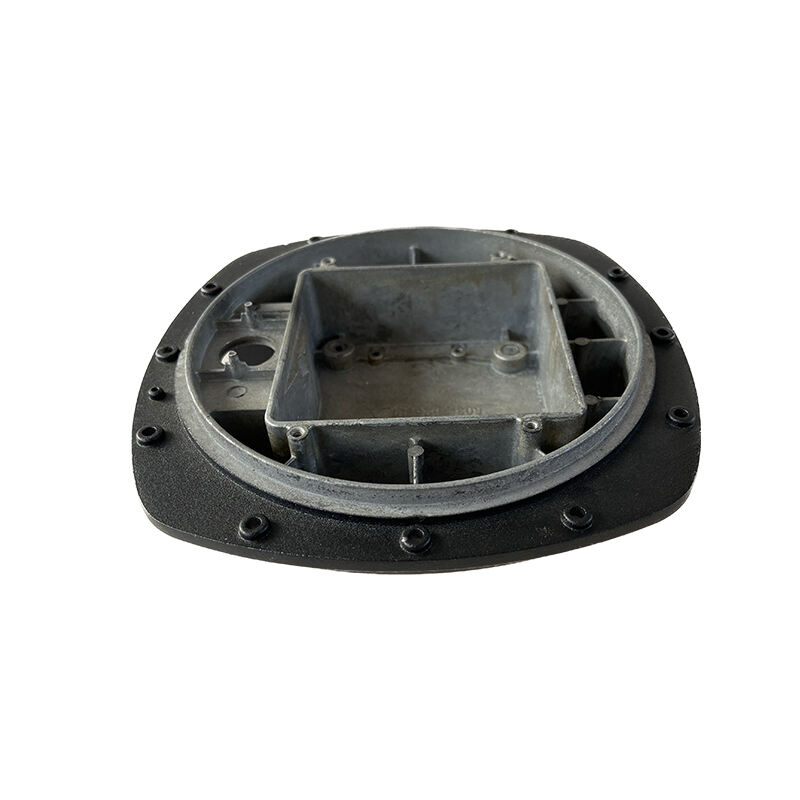

aluminium die casting products

Aluminum die casting products represent a cornerstone of modern manufacturing, offering precision-engineered components that combine durability with cost-effectiveness. This sophisticated manufacturing process involves injecting molten aluminum into reusable metal molds under high pressure, creating complex parts with exceptional dimensional accuracy and surface finish. The resulting products feature outstanding strength-to-weight ratios, excellent thermal conductivity, and superior corrosion resistance. These components find extensive applications across various industries, from automotive parts like engine blocks and transmission housings to consumer electronics housings, aerospace components, and industrial machinery parts. The process allows for the production of intricate designs with tight tolerances, thin walls, and complex geometries that would be difficult or impossible to achieve through other manufacturing methods. Additionally, aluminum die casting products offer excellent electrical conductivity and EMI shielding properties, making them ideal for electronic enclosures and telecommunications equipment. The versatility of this manufacturing process enables the creation of components ranging from small, detailed parts weighing just a few ounces to large structural elements weighing several pounds, all while maintaining consistent quality and dimensional stability.