aluminum die casting company

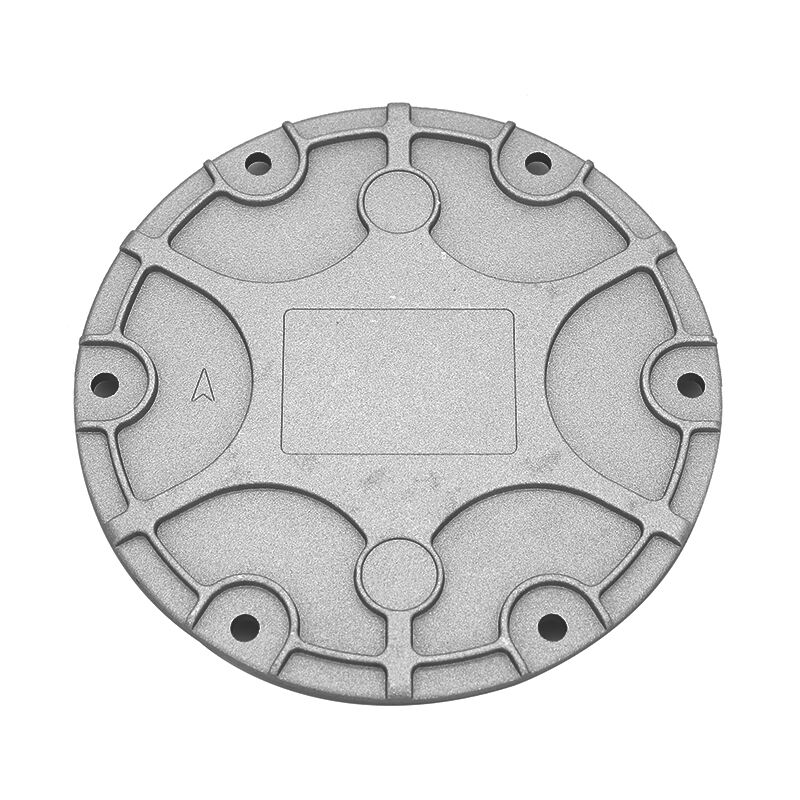

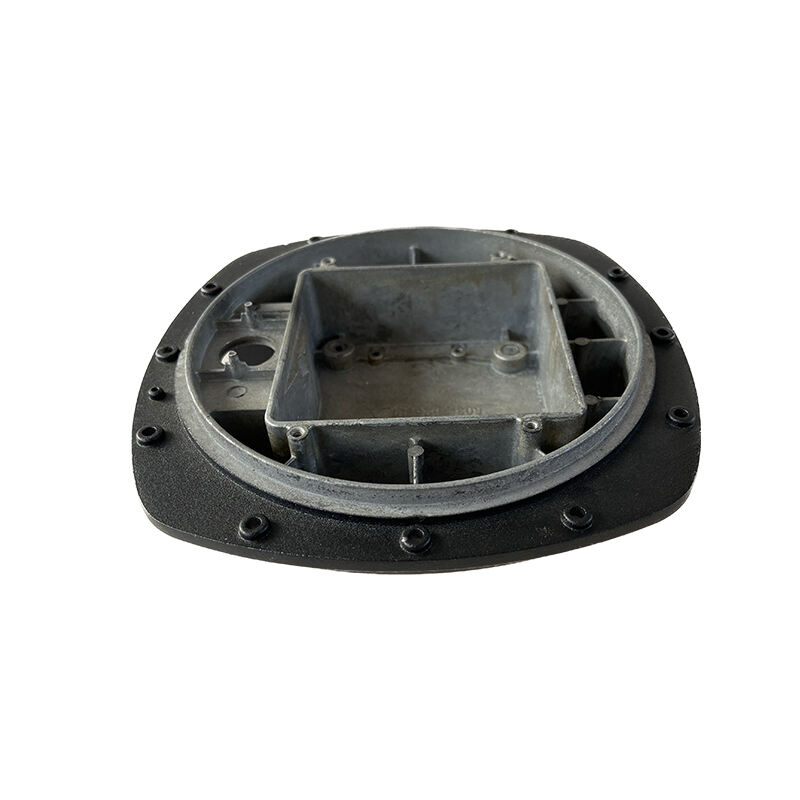

Our aluminum die casting company stands at the forefront of precision manufacturing, delivering exceptional quality components for diverse industries. With state-of-the-art facilities equipped with advanced die casting machines and automated systems, we specialize in producing complex aluminum parts with superior dimensional accuracy and consistency. Our manufacturing process incorporates computer-aided design and simulation software, ensuring optimal mold filling and solidification patterns. We utilize both hot and cold chamber die casting techniques, allowing us to accommodate various part sizes and complexities. Our expertise extends to secondary operations including CNC machining, surface finishing, and quality inspection using coordinate measuring machines. The facility maintains strict quality control measures, adhering to international standards and specifications. We serve multiple sectors including automotive, aerospace, electronics, and industrial equipment manufacturers, providing components ranging from engine parts to electronic enclosures. Our commitment to sustainability is reflected in our use of recycled aluminum and energy-efficient processes, reducing environmental impact while maintaining product excellence.