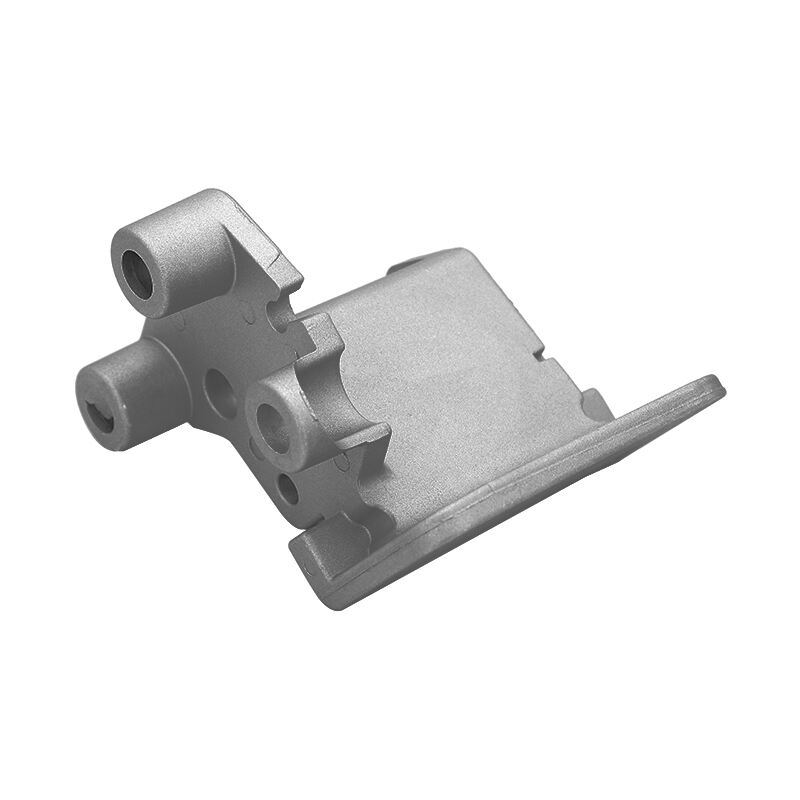

aluminium casting foundry

An aluminium casting foundry represents a sophisticated manufacturing facility dedicated to producing high-quality metal components through various casting processes. These facilities combine traditional metallurgical expertise with modern technology to transform molten aluminium into precisely engineered parts. The foundry's primary functions include melting aluminium alloys at controlled temperatures, preparing and maintaining molds, executing the casting process, and performing post-casting operations such as heat treatment and finishing. Advanced technological features include computer-controlled furnaces, automated pouring systems, and precision monitoring equipment that ensures consistent quality. The facility typically incorporates multiple casting methods, including die casting, sand casting, and permanent mold casting, each suited to different production requirements. Modern foundries also feature quality control laboratories, advanced cooling systems, and environmental control measures. These establishments serve diverse industries, from automotive and aerospace to consumer electronics and construction, producing components ranging from engine blocks and transmission cases to architectural elements and consumer product housings. The foundry's capabilities extend to producing both simple and complex geometries, with the ability to cast parts weighing from a few grams to several hundred kilograms.