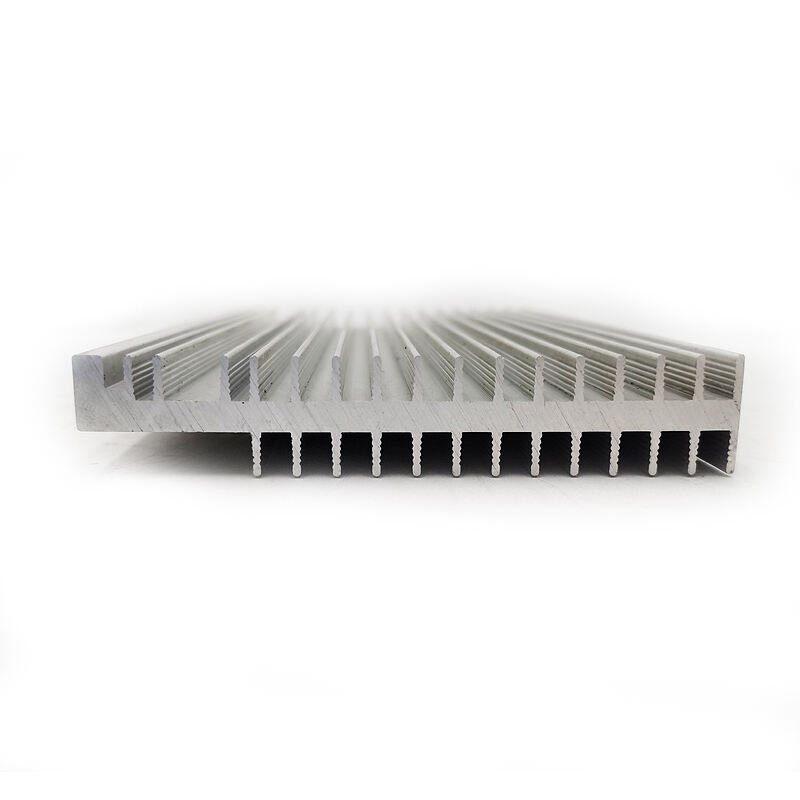

aluminium heat sink extrusion

Aluminum heat sink extrusion represents a cutting-edge thermal management solution that combines advanced manufacturing processes with optimal heat dissipation capabilities. This specialized component is engineered through a precise extrusion process, where aluminum is forced through a die to create specific profiles designed for maximum thermal efficiency. The process results in a seamless, one-piece construction that features an array of fins or pins, strategically positioned to maximize surface area for heat transfer. These heat sinks play a crucial role in maintaining optimal operating temperatures in various electronic devices and industrial applications. The extrusion process allows for customizable designs that can accommodate different cooling requirements, from simple linear fins to complex pin arrangements. The aluminum material choice is particularly significant, offering an excellent balance of thermal conductivity, weight, and cost-effectiveness. Modern heat sink extrusions incorporate sophisticated design elements such as serrated fins, cross-cut ventilation channels, and varying fin heights to optimize airflow and heat dissipation. These components are essential in applications ranging from LED lighting systems and power supplies to telecommunications equipment and automotive electronics, where efficient thermal management is crucial for system reliability and performance.