Versatile Application Integration

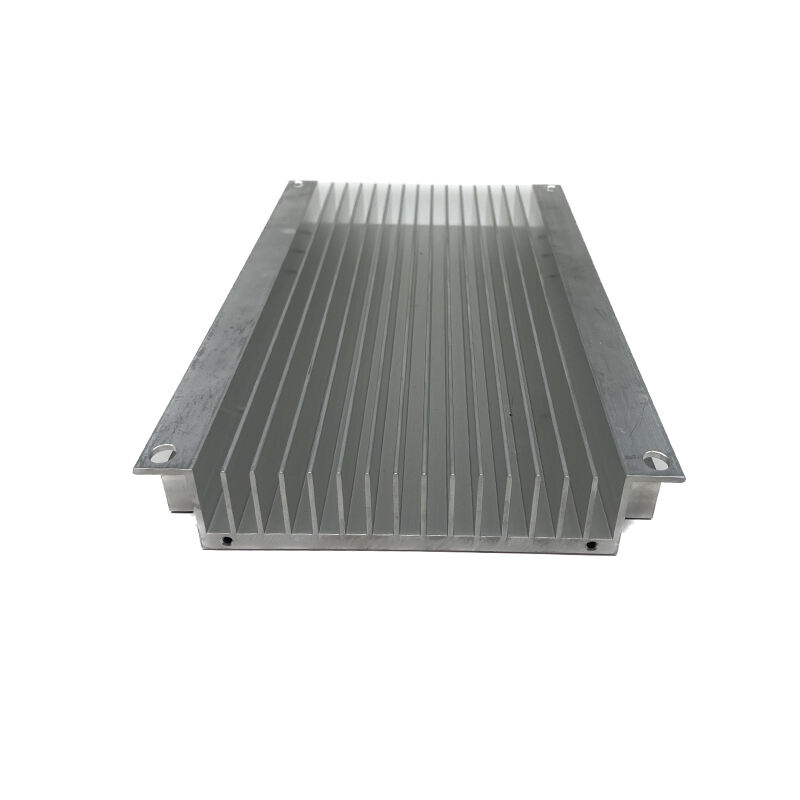

The adaptability of aluminum heatsinks makes them ideal for diverse applications across multiple industries. Their design flexibility allows for customization to meet specific thermal requirements, space constraints, and mounting configurations. Engineers can choose from various fin designs, including straight, pin, and skived fins, each optimized for particular cooling needs. The lightweight nature of aluminum enables integration into portable devices without significantly impacting overall system weight. Furthermore, these heatsinks can be manufactured with different mounting options, including clip-on systems, threaded holes, or adhesive mounting, facilitating easy installation and maintenance.