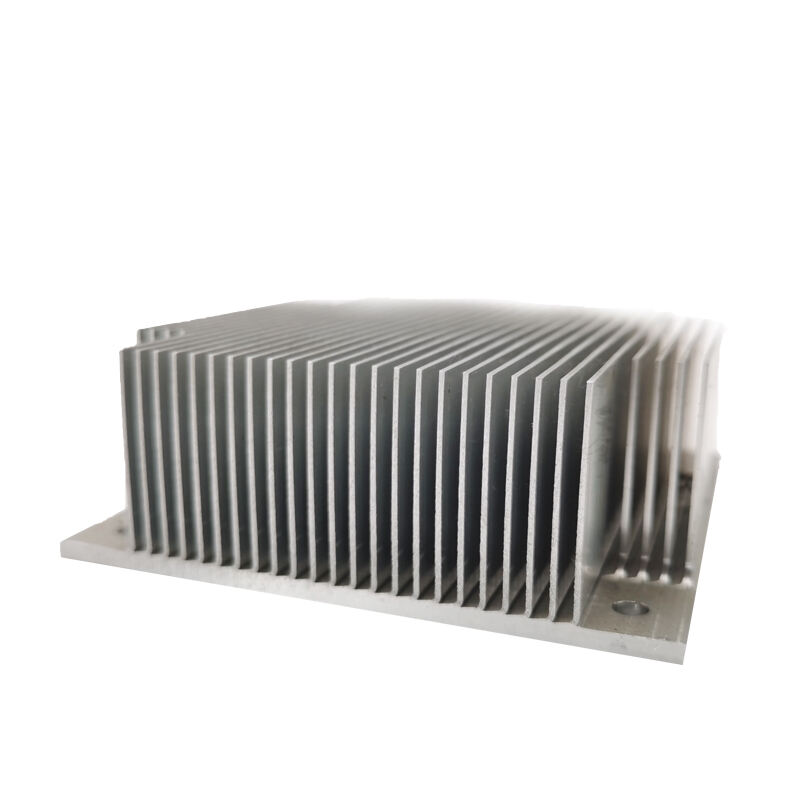

heat sink aluminium extrusion

Heat sink aluminum extrusion represents a critical advancement in thermal management technology, serving as an essential component in various electronic and industrial applications. This manufacturing process creates precisely designed aluminum profiles that efficiently dissipate heat from electronic components and systems. The extrusion process involves forcing aluminum through a die to create complex cross-sectional profiles with fins, channels, and other features that maximize surface area for optimal heat transfer. These extruded components are engineered to maintain ideal operating temperatures in devices ranging from LED lighting systems to power supplies and computer processors. The aluminum used in these extrusions offers an excellent combination of thermal conductivity, lightweight properties, and corrosion resistance. Modern heat sink extrusions incorporate sophisticated design elements such as pin fins, straight fins, or custom geometries that enhance airflow and heat dissipation capabilities. The manufacturing process ensures consistent quality and allows for the creation of various sizes and configurations to meet specific thermal management requirements across different industries.