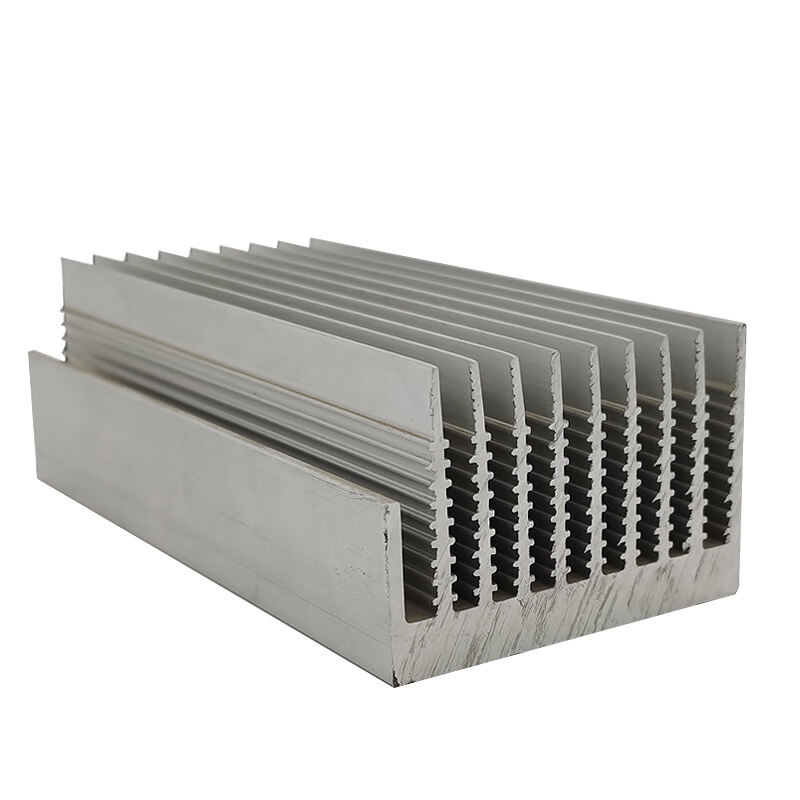

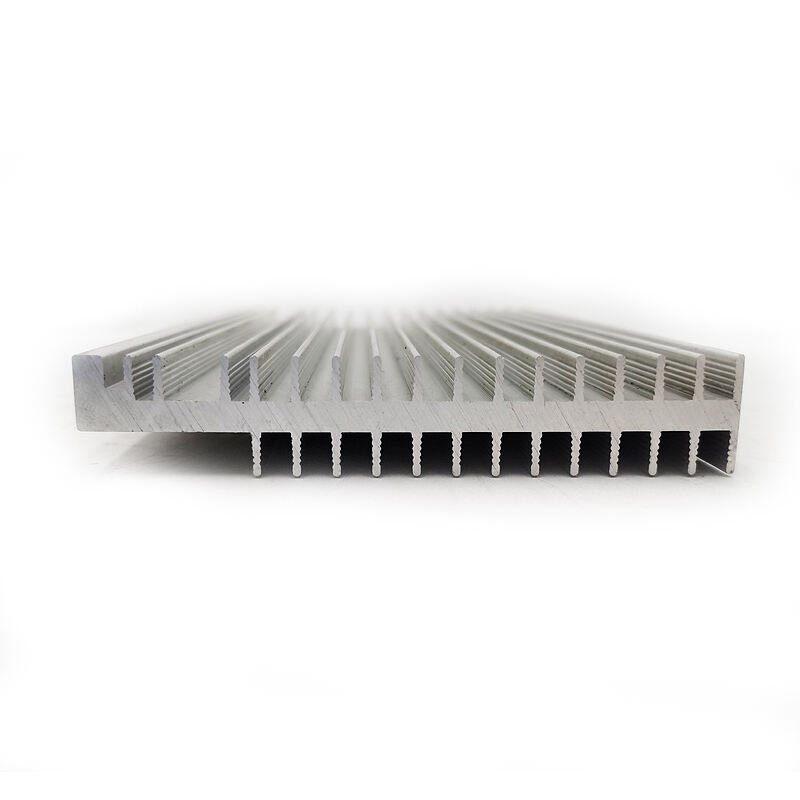

aluminum heat sink extrusion

Aluminum heat sink extrusion represents a critical thermal management solution in modern electronics and industrial applications. This sophisticated manufacturing process creates precisely designed aluminum profiles that efficiently dissipate heat from various components and systems. The extrusion process involves pushing aluminum through a die to create specific cross-sectional profiles, resulting in optimized heat sink designs with fins and channels that maximize surface area for heat dissipation. These extruded heat sinks feature excellent thermal conductivity properties, thanks to aluminum's natural characteristics and the strategic design of their surface geometry. The manufacturing process allows for customizable fin heights, spacing, and base thickness, enabling engineers to meet specific thermal requirements for different applications. Aluminum heat sink extrusions find widespread use in LED lighting systems, power electronics, automotive components, telecommunications equipment, and industrial machinery. The versatility of the extrusion process enables the creation of both standard and custom profiles, making it possible to address varying thermal management needs across different industries. These heat sinks also incorporate mounting points and other functional features directly into the extrusion design, streamlining assembly processes and reducing overall system costs.