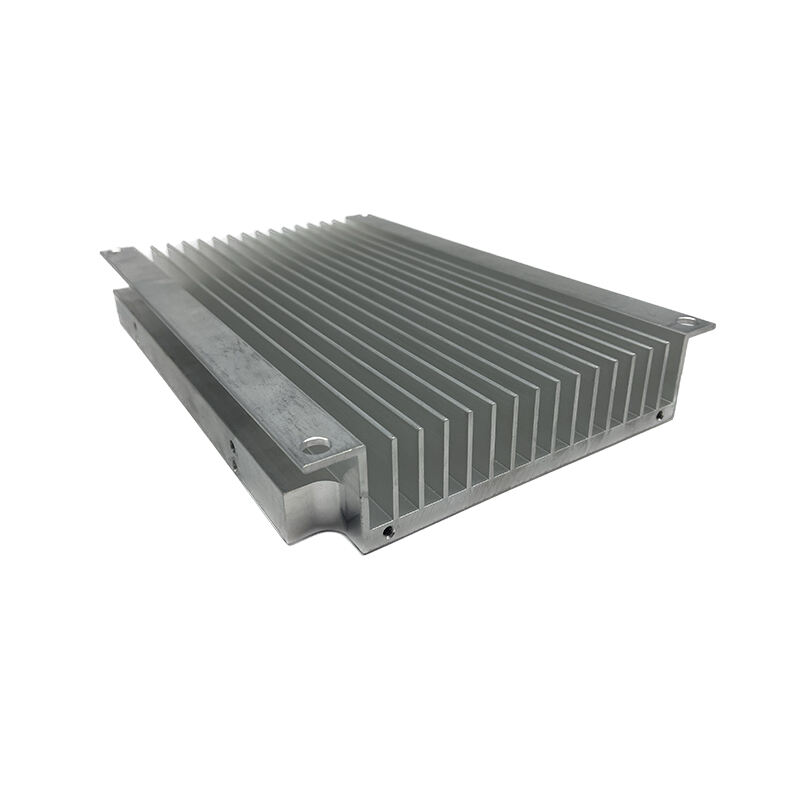

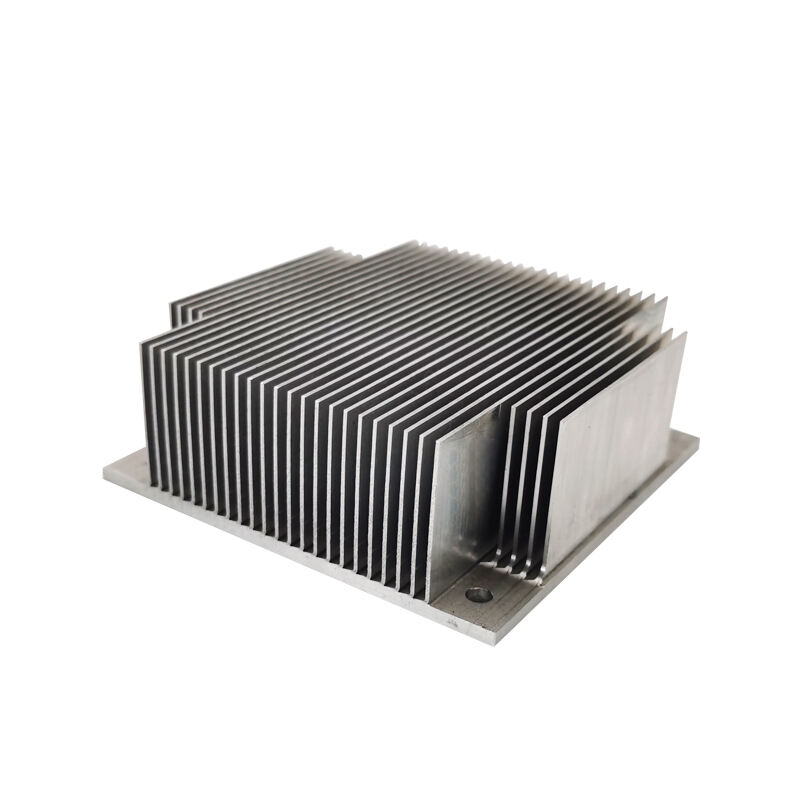

extruded heat sink

Extruded heat sinks are precision engineered thermal management solutions designed to efficiently dissipate heat from electronic components and systems. These essential cooling devices are manufactured through an aluminum extrusion process, which creates a uniform profile with multiple fins extending from a base plate. The extrusion process allows for complex cross sectional designs that maximize surface area while maintaining structural integrity. Each fin serves as a thermal pathway, conducting heat away from the source and releasing it into the surrounding air through convection. The base plate provides excellent thermal conductivity and ensures even heat distribution across the entire surface. Modern extruded heat sinks incorporate advanced design features such as serrated fins, cross cut ventilation channels, and optimized fin spacing to enhance thermal performance. These heat sinks are particularly valuable in applications requiring reliable cooling solutions, including power electronics, LED lighting systems, telecommunications equipment, and industrial machinery. The versatility of the extrusion process enables manufacturers to create custom profiles tailored to specific thermal requirements, making these heat sinks adaptable to various mounting configurations and space constraints.