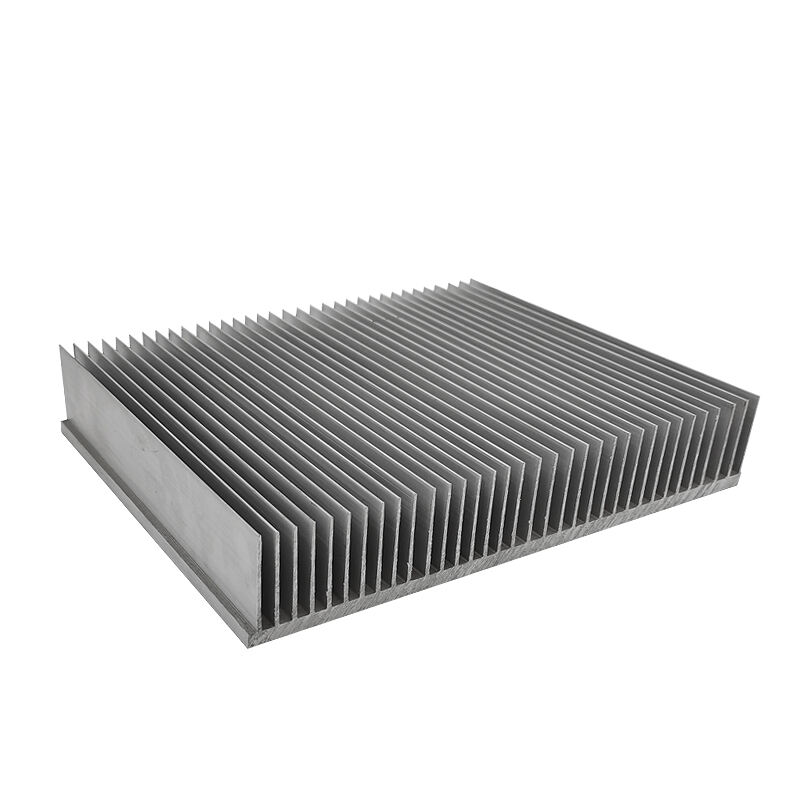

custom aluminum heatsink

Custom aluminum heatsinks represent a crucial advancement in thermal management technology, offering tailored cooling solutions for various electronic applications. These precision-engineered components are designed to efficiently dissipate heat from electronic devices, ensuring optimal performance and extended lifespan of critical equipment. The custom aluminum heatsink utilizes high-grade aluminum alloys, chosen for their excellent thermal conductivity and cost-effectiveness. Through advanced manufacturing processes, including CNC machining and precision die-casting, these heatsinks can be produced with intricate fin designs and specific dimensional requirements to meet unique cooling demands. The design incorporates strategic fin arrangements and surface area optimization to maximize heat transfer capabilities while maintaining compact form factors. These heatsinks are particularly valuable in applications ranging from power electronics and LED lighting to telecommunications equipment and industrial machinery. The customization options extend to surface treatments, mounting mechanisms, and thermal interface considerations, ensuring compatibility with various installation requirements. The flexibility in design allows for integration with different cooling methods, including natural convection, forced-air cooling, and liquid cooling systems, making them versatile solutions for diverse thermal management challenges.