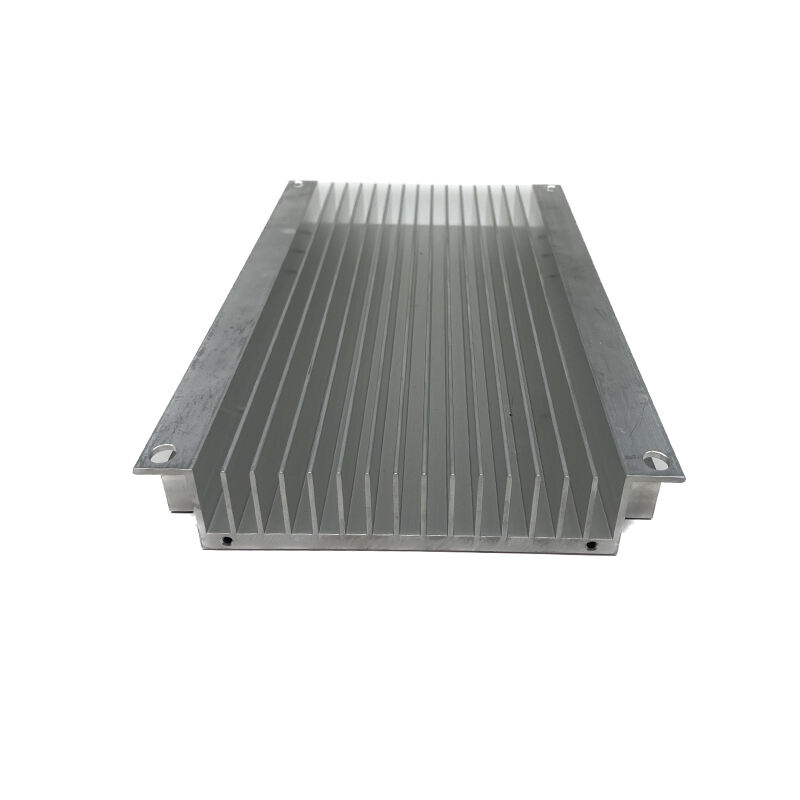

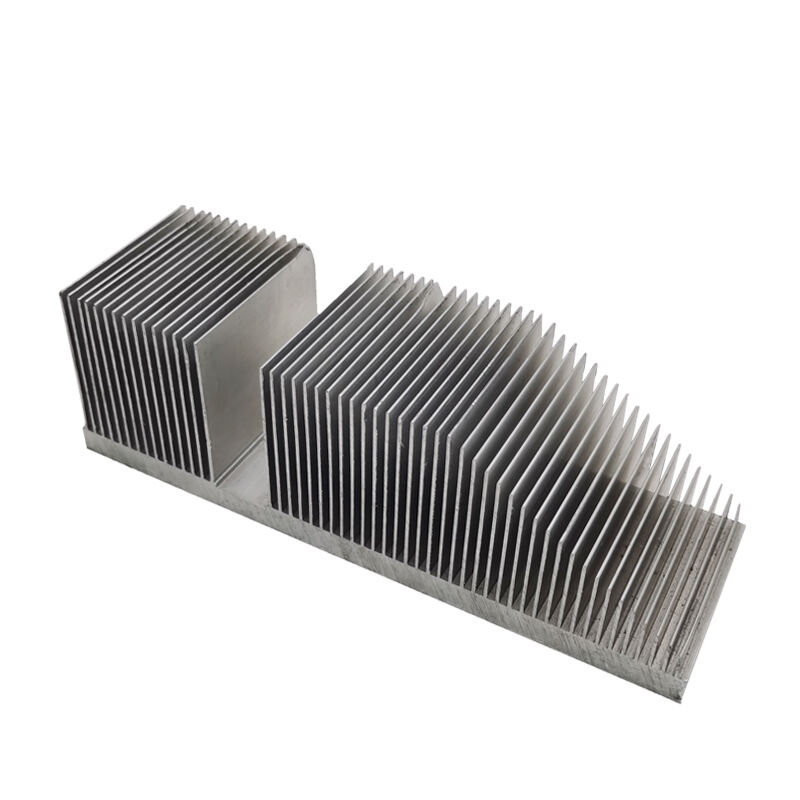

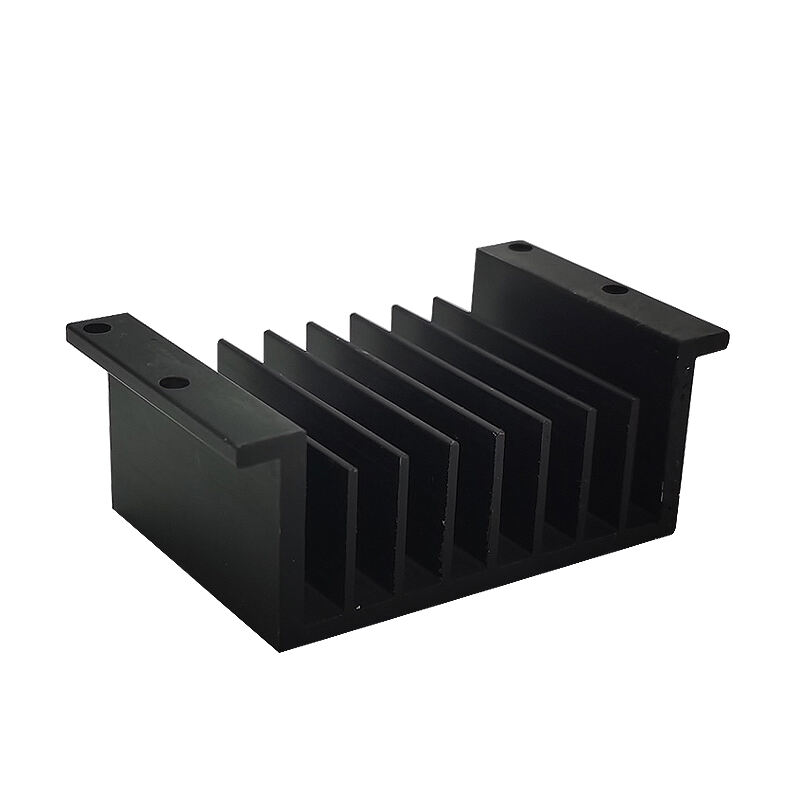

heat sink profile

A heat sink profile represents a crucial component in thermal management systems, engineered to efficiently dissipate heat from electronic devices and industrial equipment. These precisely designed aluminum or copper structures feature an array of fins or pins that maximize surface area for optimal heat transfer. The profile's construction typically incorporates advanced thermal conductivity materials and specialized geometries that facilitate natural or forced air convection. Modern heat sink profiles utilize cutting-edge manufacturing techniques, including extrusion and CNC machining, to achieve precise dimensional tolerances and surface finishes. These profiles are essential in maintaining optimal operating temperatures for various applications, from high-performance computing systems to LED lighting fixtures and power electronics. The design incorporates thermal resistance optimization, ensuring efficient heat transfer from the source to the ambient environment. Heat sink profiles often feature mounting provisions and thermal interface material compatibility, enabling seamless integration with electronic components. Their scalable nature allows for customization across different size requirements and thermal loads, making them versatile solutions for diverse cooling needs.