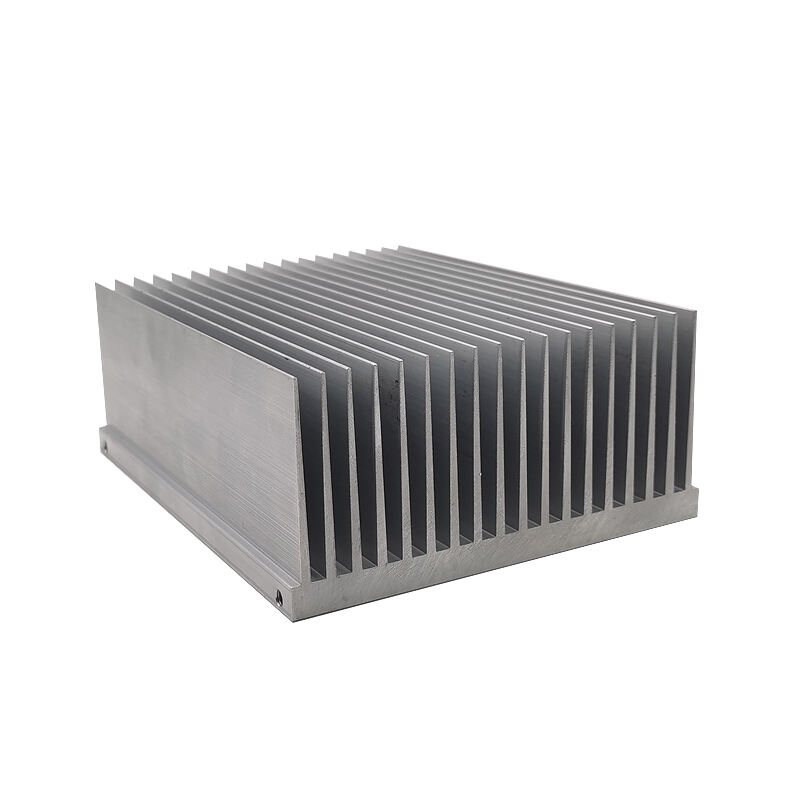

aluminum heat sink

An aluminum heat sink is a crucial thermal management component designed to efficiently dissipate heat from electronic devices and industrial equipment. This passive cooling solution features a base plate that makes direct contact with the heat source, coupled with an array of fins or pins that significantly increase the surface area available for heat transfer. The design leverages aluminum's excellent thermal conductivity and lightweight properties to effectively transfer heat from the source to the surrounding air. Heat sinks operate through the principle of conduction and convection, where heat moves from the hot device through the aluminum base and is then dispersed into the environment via the extended surfaces. Modern aluminum heat sinks incorporate advanced designs such as cross-cut fins, skived fins, or bonded fins to maximize cooling efficiency. These thermal management solutions are extensively used in various applications, including LED lighting systems, power supplies, computer processors, automotive electronics, and industrial machinery. The versatility of aluminum heat sinks allows for customization in size, shape, and fin configuration to meet specific cooling requirements while maintaining cost-effectiveness.