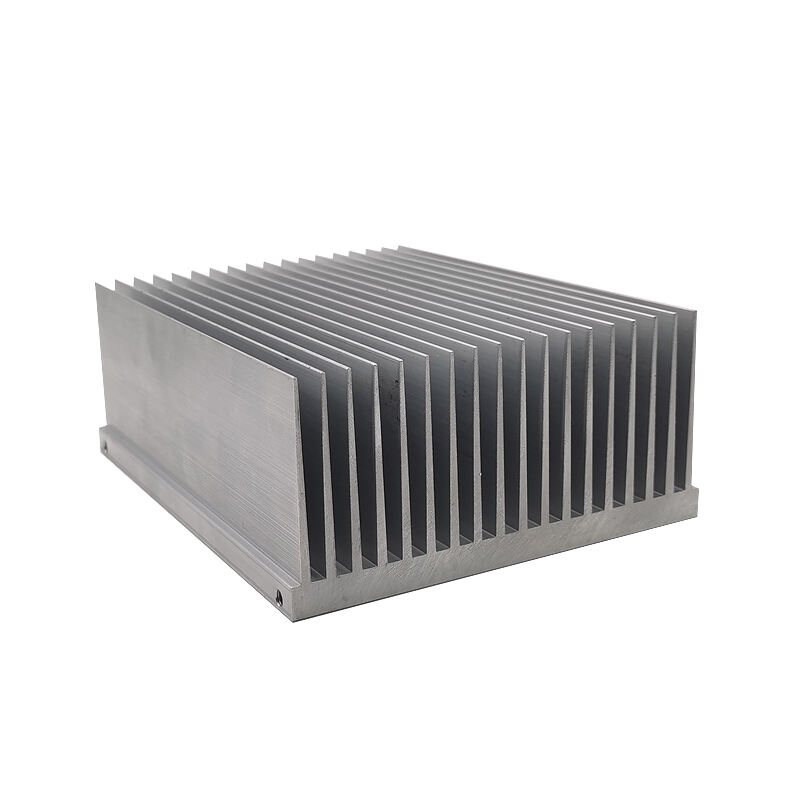

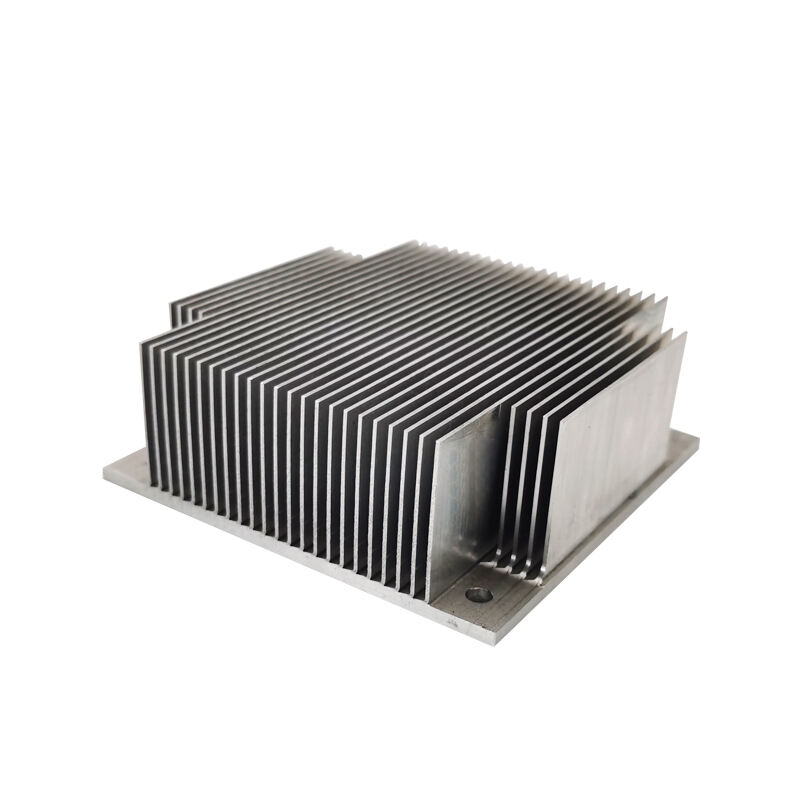

aluminium heatsink profile

The aluminum heatsink profile represents a crucial component in thermal management systems, engineered specifically for efficient heat dissipation in various electronic applications. This precision-engineered thermal solution features carefully designed fins and channels that maximize surface area for optimal heat transfer from electronic components to the surrounding air. The profile is manufactured through an extrusion process that ensures uniform material distribution and consistent thermal performance. With its excellent thermal conductivity of approximately 205 W/m·K, aluminum heatsink profiles effectively manage heat in applications ranging from LED lighting systems to power electronics and industrial equipment. The design incorporates multiple mounting options and can be customized to specific dimensional requirements, making it versatile for different installation scenarios. The surface treatment options, including anodizing and powder coating, not only enhance corrosion resistance but also improve the overall thermal performance. The profile's structural integrity allows for extended operational lifespan while maintaining consistent cooling efficiency throughout its service life.