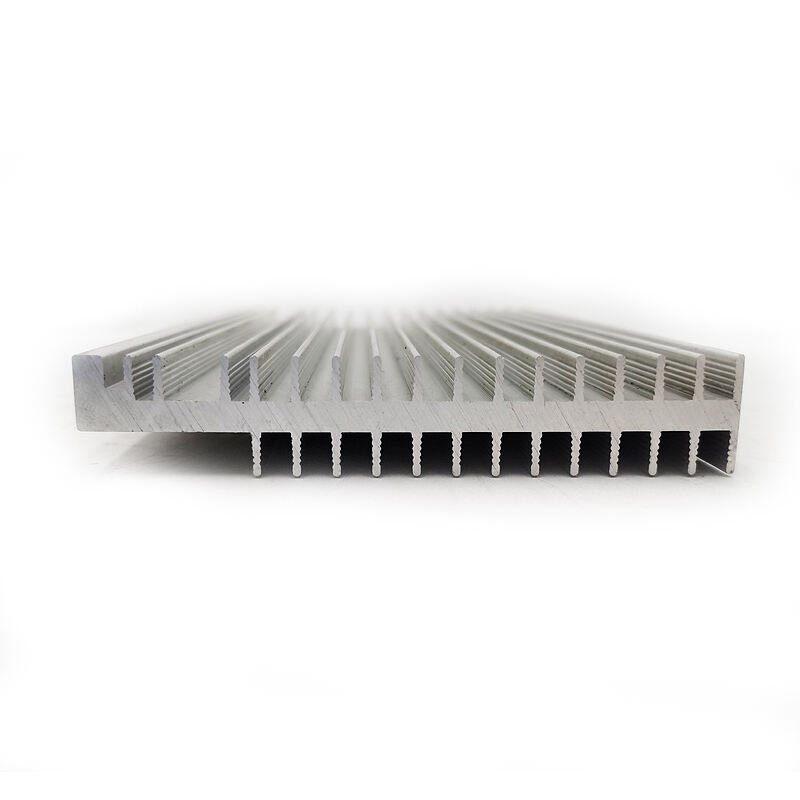

extruded aluminum heatsinks

Extruded aluminum heatsinks represent a crucial component in thermal management solutions, engineered to efficiently dissipate heat from electronic devices and systems. These heatsinks are manufactured through a precision aluminum extrusion process, resulting in a seamless, one-piece design with optimized fin configurations. The base material, typically high-grade aluminum alloy, offers exceptional thermal conductivity while maintaining a lightweight profile. The extrusion process allows for customizable fin heights, thicknesses, and spacing, enabling optimal heat dissipation for specific applications. These heatsinks feature a series of parallel fins that maximize surface area contact with surrounding air, facilitating enhanced heat transfer through both convection and conduction principles. The design incorporates advanced thermal engineering concepts, ensuring uniform heat distribution across the entire surface area. Modern extruded aluminum heatsinks often include additional features such as mounting holes, cutouts, and surface treatments to improve thermal performance and installation flexibility. They find extensive applications in power electronics, LED lighting systems, industrial control equipment, telecommunications infrastructure, and computer hardware, where efficient thermal management is critical for maintaining optimal operating temperatures and ensuring long-term reliability.