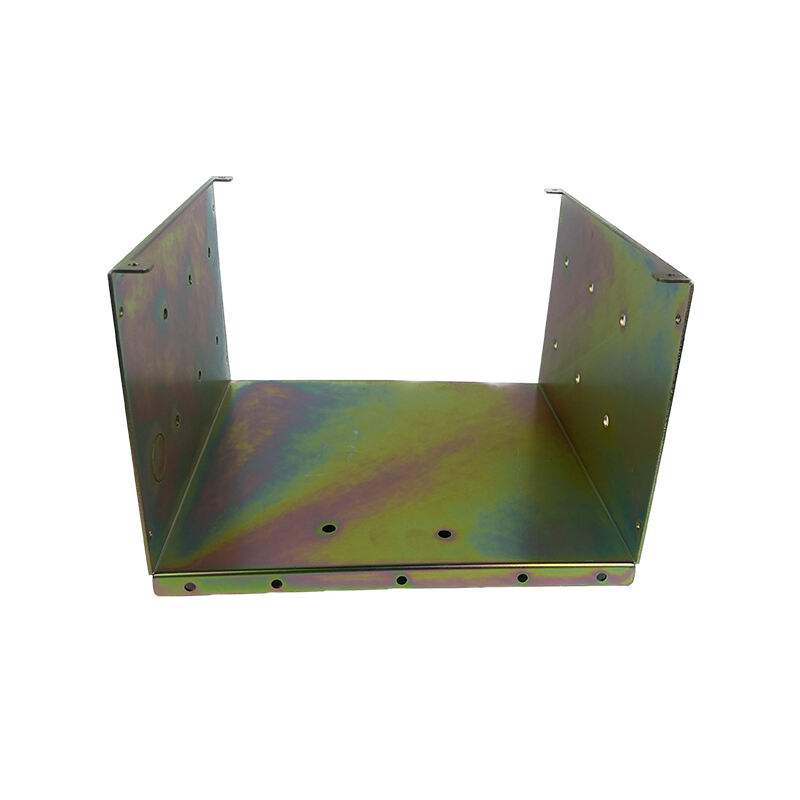

stainless steel stamping parts

Stainless steel stamping parts represent a cornerstone of modern manufacturing, combining durability with precision engineering. These components are produced through a sophisticated stamping process that involves cutting, forming, and shaping stainless steel sheets into specific configurations. The manufacturing process utilizes advanced die technology and high-precision machinery to ensure consistent quality and dimensional accuracy. These parts exhibit exceptional corrosion resistance, maintaining their integrity even in challenging environments. The versatility of stainless steel stamping extends across various industries, from automotive and aerospace to medical equipment and consumer electronics. The process allows for high-volume production while maintaining tight tolerances and superior surface finishes. Modern stamping techniques incorporate computer-aided design and automation, enabling the creation of complex geometries and intricate details. The parts can be customized to meet specific requirements, whether it's thickness variations, special coating applications, or unique structural features. Quality control measures, including material testing and dimensional verification, ensure that each component meets stringent industry standards.