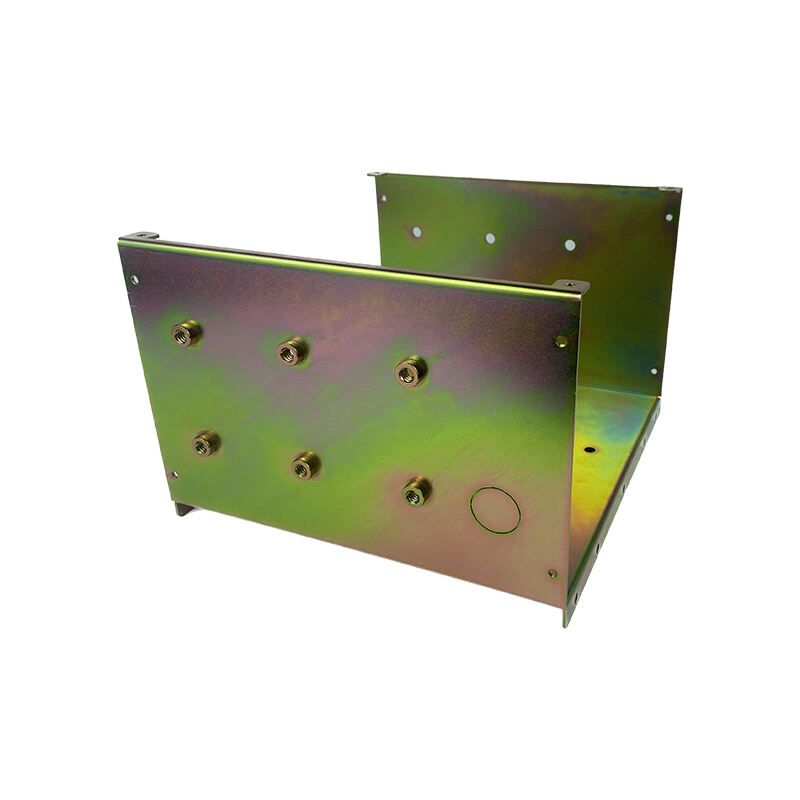

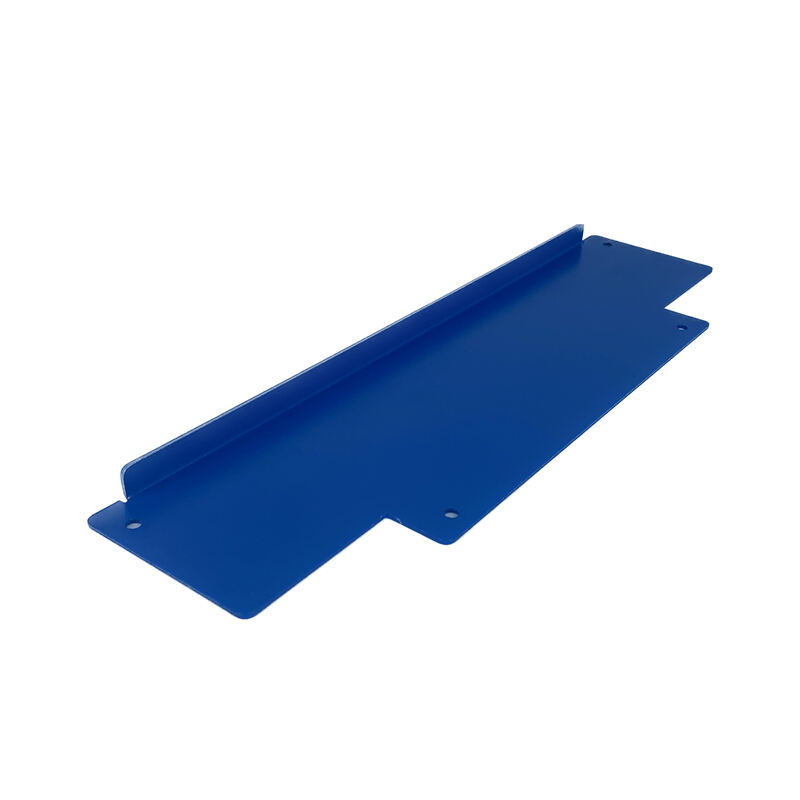

automotive metal stamping parts

Automotive metal stamping parts represent a cornerstone of modern vehicle manufacturing, encompassing a wide range of components produced through precise mechanical processes. These parts are manufactured using specialized stamping techniques that involve forming metal sheets into specific shapes through compression, punching, and bending operations. The process utilizes advanced dies and tools to create components with exceptional dimensional accuracy and structural integrity. These parts find extensive applications throughout a vehicle's structure, from body panels and chassis components to smaller brackets and reinforcements. The manufacturing process incorporates state-of-the-art automation and quality control systems, ensuring consistent production of high-quality components that meet strict automotive industry standards. The versatility of metal stamping allows for the creation of both simple and complex geometries, making it possible to produce parts ranging from flat brackets to intricate three-dimensional components. Modern automotive metal stamping facilities employ sophisticated computer-aided design (CAD) and manufacturing systems to optimize production efficiency and maintain precise tolerances. These parts are essential for vehicle safety, structural integrity, and overall performance, contributing significantly to the durability and reliability of modern automobiles.