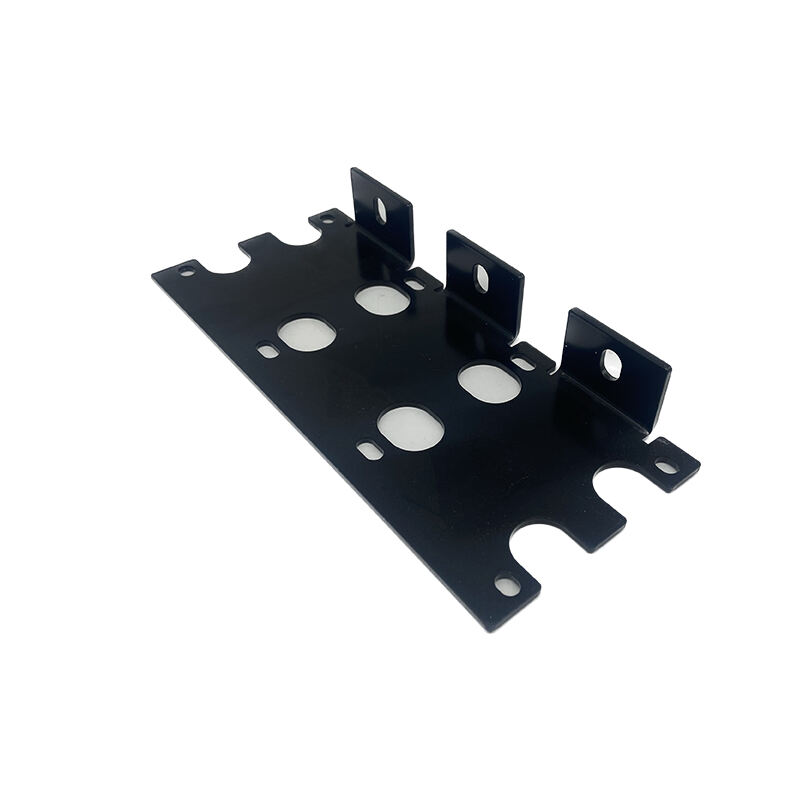

stainless steel stamping

Stainless steel stamping is a sophisticated manufacturing process that transforms flat metal sheets into precise, three-dimensional components through controlled deformation. This versatile technique combines advanced hydraulic or mechanical presses with specialized dies to create complex shapes and forms while maintaining the inherent corrosion resistance and durability of stainless steel. The process involves multiple stages, including blanking, piercing, forming, and finishing, each precisely controlled to ensure optimal results. Modern stainless steel stamping operations utilize computer-controlled equipment and automated systems to maintain consistent quality and high production rates. The technology finds extensive applications across various industries, from automotive components and household appliances to medical devices and aerospace parts. The precision of modern stamping equipment allows for tolerances as tight as ±0.1mm, ensuring exceptional accuracy in the final products. This manufacturing method is particularly valued for its ability to produce complex components with minimal material waste, making it both economically and environmentally advantageous.