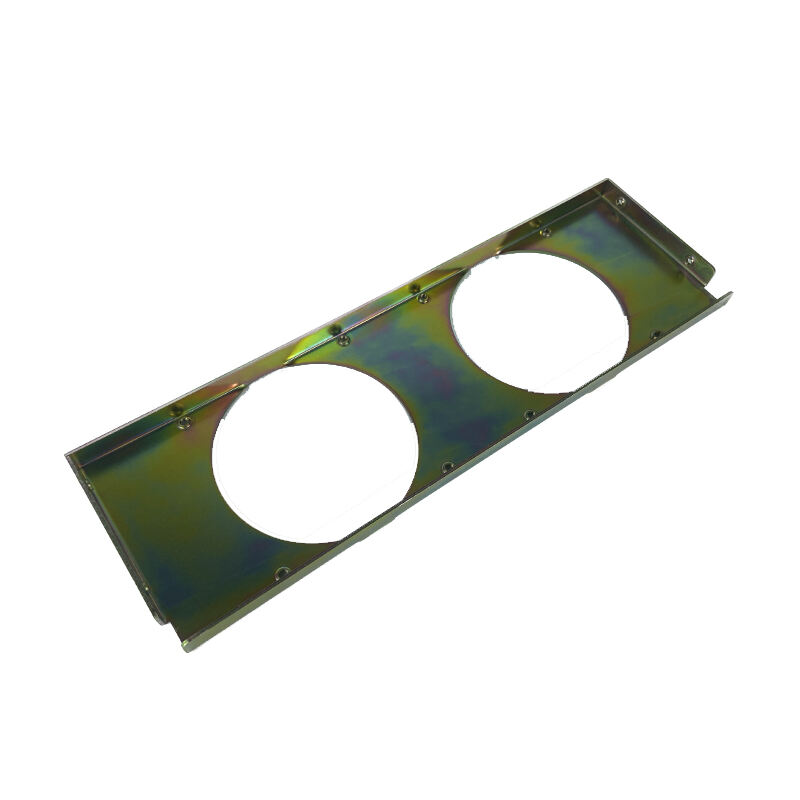

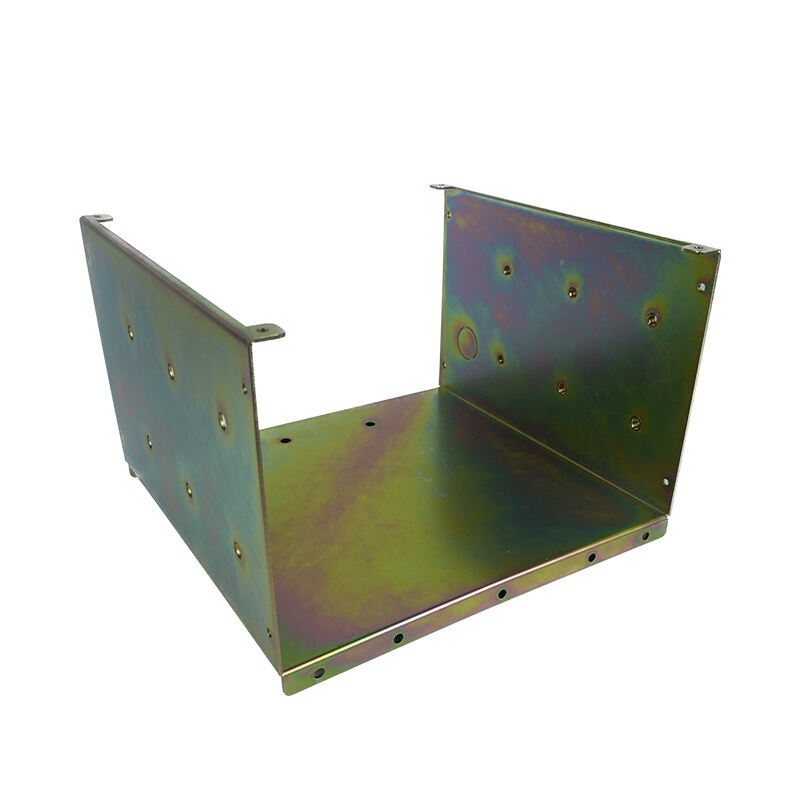

aluminum stamping parts

Aluminum stamping parts represent a crucial component in modern manufacturing, combining precision engineering with cost-effective production methods. These components are produced through a sophisticated stamping process that involves forming aluminum sheets into specific shapes using specialized dies and high-pressure machinery. The process encompasses various techniques including blanking, piercing, bending, and forming, allowing for the creation of complex geometries while maintaining tight tolerances. Aluminum stamping parts excel in applications requiring lightweight yet durable components, making them ideal for automotive, aerospace, electronics, and consumer goods industries. The manufacturing process ensures consistent quality across large production runs while minimizing material waste. These parts feature excellent corrosion resistance, superior thermal conductivity, and remarkable strength-to-weight ratios. Modern aluminum stamping techniques incorporate advanced CAD/CAM systems and automated quality control measures, ensuring precise dimensional accuracy and repeatability. The versatility of aluminum stamping allows for the production of both simple and intricate components, ranging from electronic housings to structural supports, while maintaining cost-effectiveness and rapid production capabilities.