injection mould manufacturing

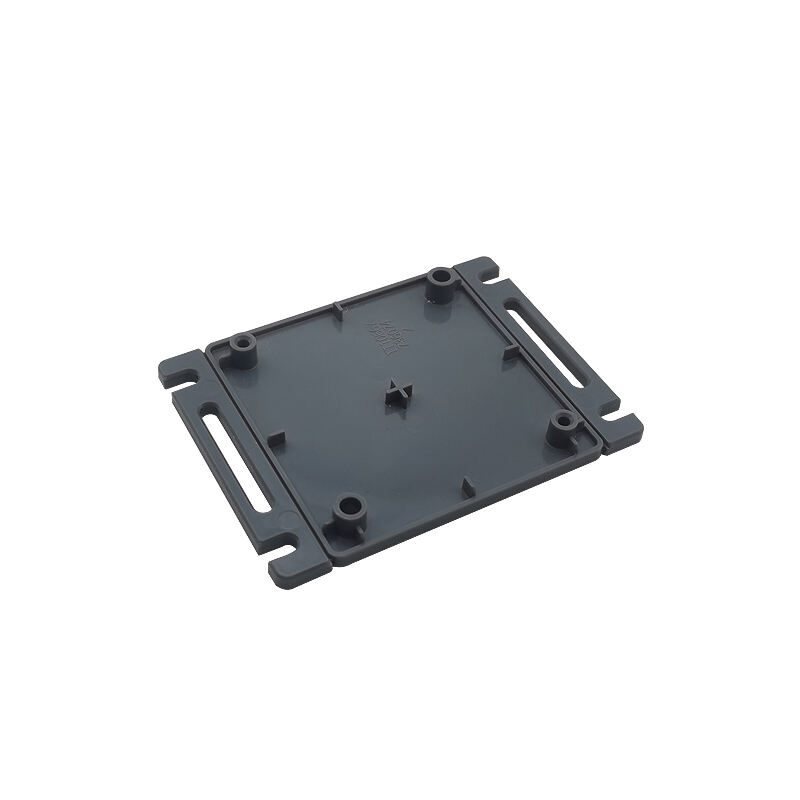

Injection mould manufacturing represents a cornerstone technology in modern industrial production, enabling the mass production of complex plastic components with exceptional precision and consistency. This sophisticated manufacturing process involves creating precision engineered molds, typically crafted from high grade steel, which serve as negative cavities into which molten plastic material is injected under high pressure. The process encompasses multiple critical stages, from initial design and prototyping to final production, utilizing advanced CAD/CAM systems and precision machining techniques. These molds are engineered to withstand extreme pressure and temperature conditions while maintaining dimensional accuracy throughout thousands of production cycles. The technology incorporates various sophisticated features including cooling channels, ejector systems, and complex gate designs that ensure optimal material flow and product quality. Modern injection mold manufacturing facilities employ state of the art CNC machining centers, EDM equipment, and quality control systems to achieve tolerances as precise as 0.01mm. The applications span across numerous industries, from automotive and consumer electronics to medical devices and aerospace components, making it an indispensable technology in contemporary manufacturing.