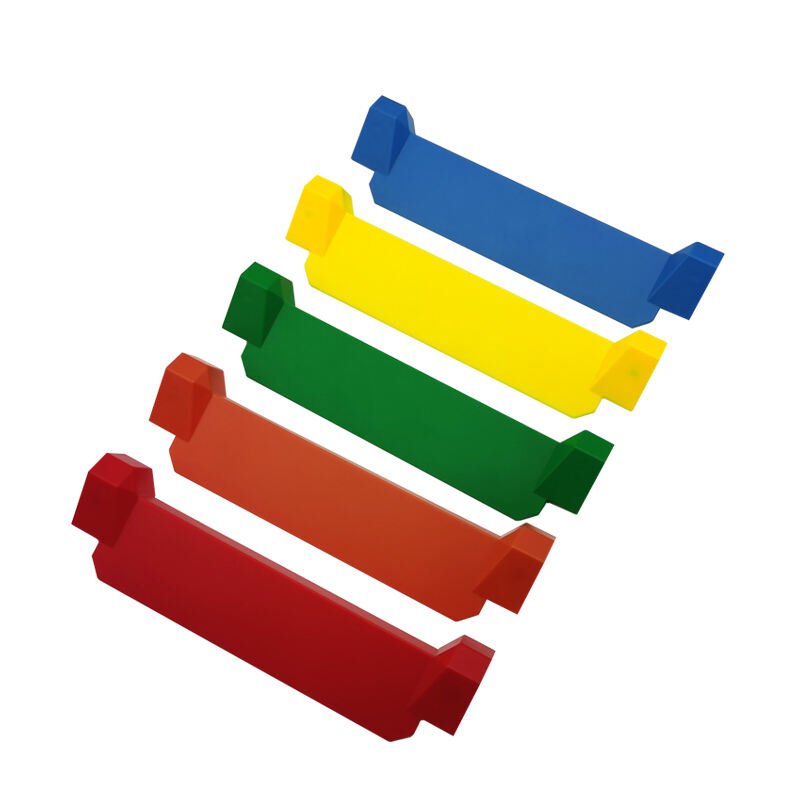

abs plastic

ABS plastic, or Acrylonitrile Butadiene Styrene, stands as a versatile engineering polymer that has revolutionized manufacturing across multiple industries. This thermoplastic material combines the strength and rigidity of acrylonitrile and styrene polymers with the toughness of polybutadiene rubber. The resulting material exhibits remarkable mechanical properties, including high impact resistance, structural strength, and excellent dimensional stability. ABS plastic maintains its robust performance across a wide temperature range and demonstrates exceptional resistance to chemical corrosion. Its processing versatility allows for various manufacturing methods, including injection molding, extrusion, and 3D printing. The material's surface finish can be easily modified through painting, gluing, or other secondary processes, making it ideal for both functional and aesthetic applications. Common applications include automotive parts, consumer electronics housings, household appliances, toys, and medical devices. The material's ability to be modified with additives further enhances its properties, allowing manufacturers to customize characteristics such as flame retardancy, UV resistance, and color stability. This adaptability, combined with its cost-effectiveness and reliable performance, has established ABS plastic as a cornerstone material in modern manufacturing.