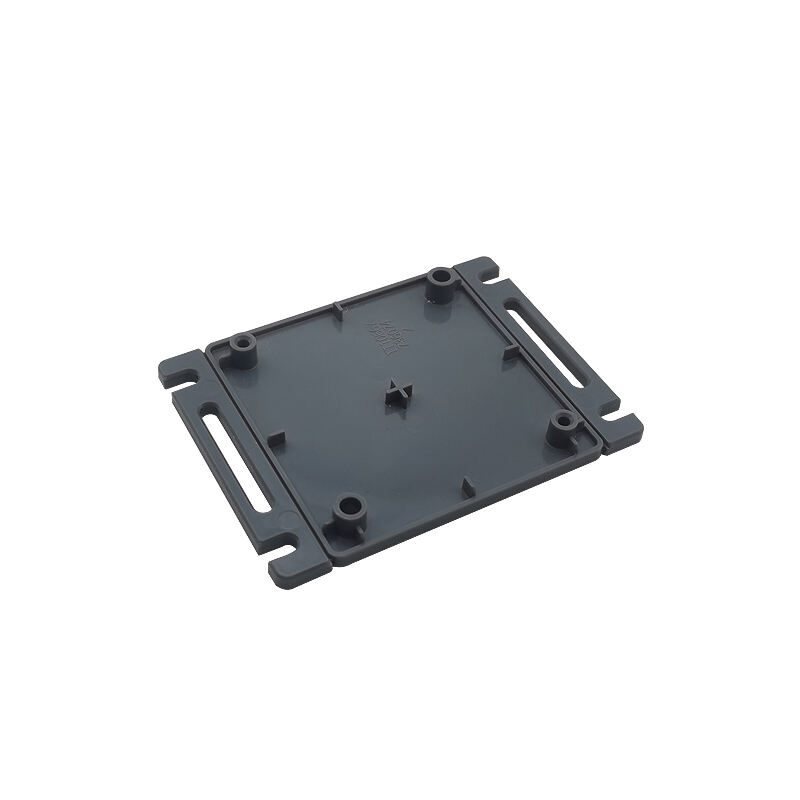

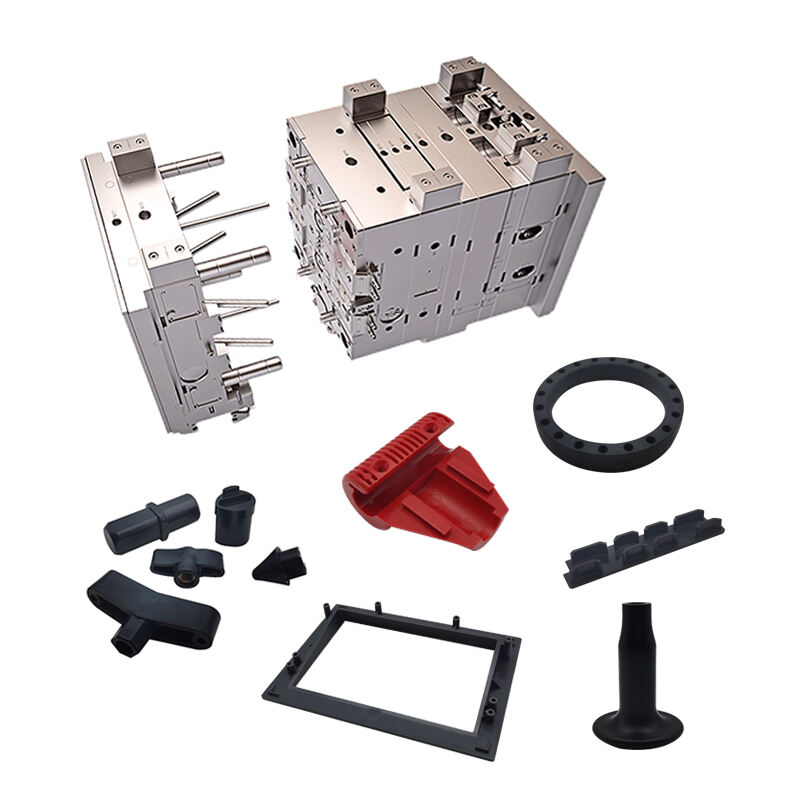

molding injection plastic

Injection molding plastic is a revolutionary manufacturing process that has transformed modern production capabilities. This sophisticated technology involves injecting molten plastic material into a precisely engineered mold cavity under high pressure. The process begins with plastic pellets being heated until they reach a molten state, then the material is forcefully injected into the mold where it cools and solidifies into the desired shape. The versatility of injection molding allows for the creation of complex geometries with excellent dimensional accuracy and surface finish. This manufacturing method is particularly noteworthy for its ability to produce large volumes of identical parts with remarkable consistency and efficiency. The technology incorporates advanced features such as precise temperature control systems, automated material handling, and sophisticated pressure monitoring to ensure optimal product quality. Common applications span across numerous industries, including automotive components, consumer electronics housings, medical devices, household items, and packaging solutions. The process supports a wide range of thermoplastic materials, each offering specific properties suitable for different applications. Modern injection molding machines are equipped with smart controls and monitoring systems that enable real-time quality control and process optimization, making it an indispensable technology in contemporary manufacturing.