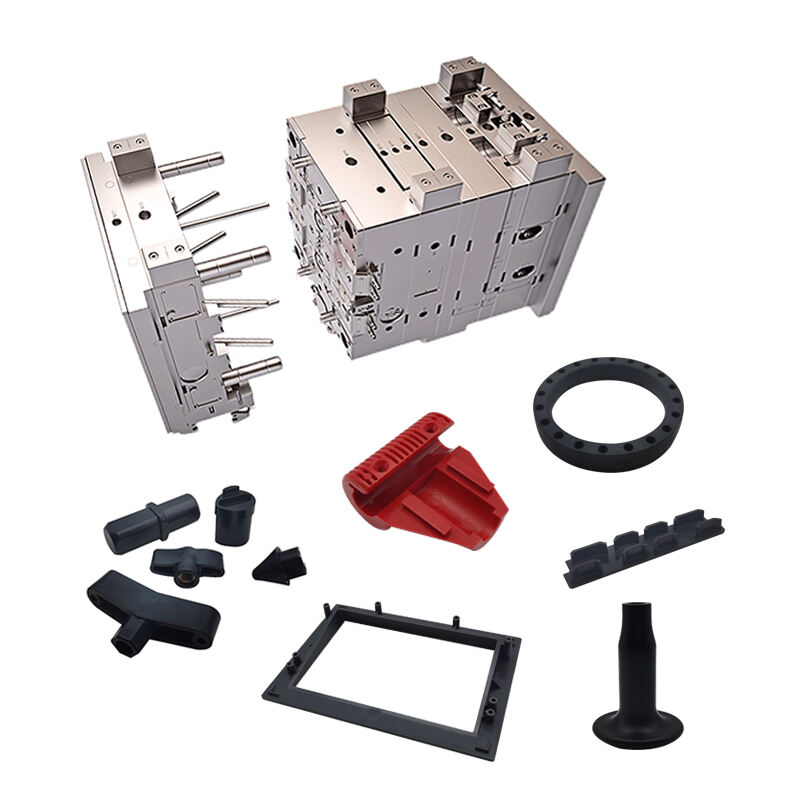

plastic injection

Plastic injection molding is a revolutionary manufacturing process that transforms raw plastic materials into precisely engineered products through a sophisticated combination of heat, pressure, and cooling. This versatile technology involves melting plastic pellets and injecting the molten material into carefully designed molds, where it solidifies to create complex parts with exceptional accuracy. The process begins with the loading of plastic granules into a heated barrel, where they are melted to achieve optimal flow characteristics. The liquefied plastic is then forcefully injected into a temperature-controlled mold cavity under high pressure, ensuring complete filling of all spaces and intricate details. Advanced cooling systems within the mold facilitate rapid solidification, maintaining dimensional stability and surface quality. Modern plastic injection systems incorporate sophisticated controls for temperature, pressure, and timing, enabling manufacturers to produce consistent, high-quality parts with minimal waste. This technology serves diverse industries, from automotive and consumer electronics to medical devices and household products, offering unparalleled flexibility in design possibilities and production efficiency.