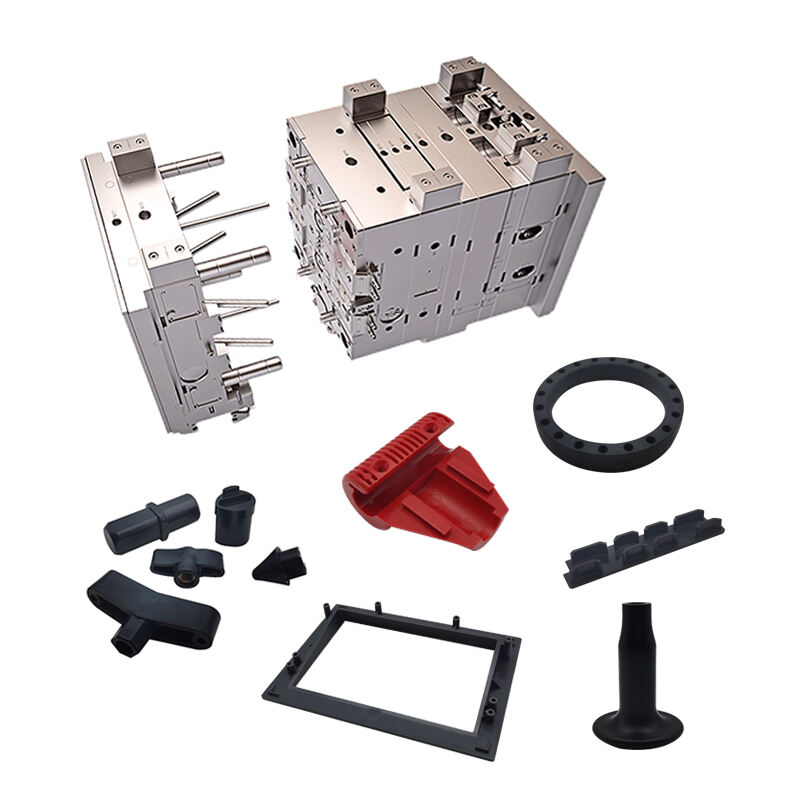

custom abs parts

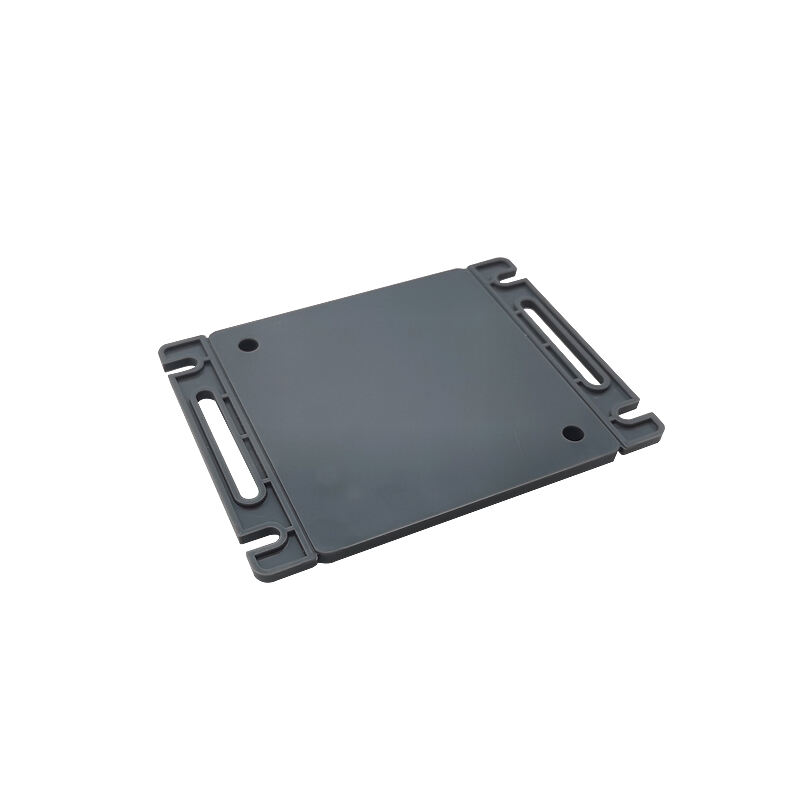

Custom ABS parts represent a significant advancement in manufacturing technology, offering tailored solutions for diverse industrial applications. These components, crafted from Acrylonitrile Butadiene Styrene (ABS), combine durability, flexibility, and cost-effectiveness. The manufacturing process involves precision injection molding, allowing for intricate designs and tight tolerances while maintaining consistent quality across production runs. These parts excel in applications requiring impact resistance, chemical stability, and thermal durability, making them ideal for automotive components, consumer electronics, medical devices, and industrial equipment. The customization capabilities extend to color options, surface finishes, and specific mechanical properties, ensuring that each part meets exact specifications. Modern manufacturing techniques enable rapid prototyping and production scaling, while quality control measures ensure each component meets stringent industry standards. The versatility of custom ABS parts allows for complex geometries and integrated features that would be difficult or impossible to achieve with other materials, providing engineers and designers with greater freedom in product development.