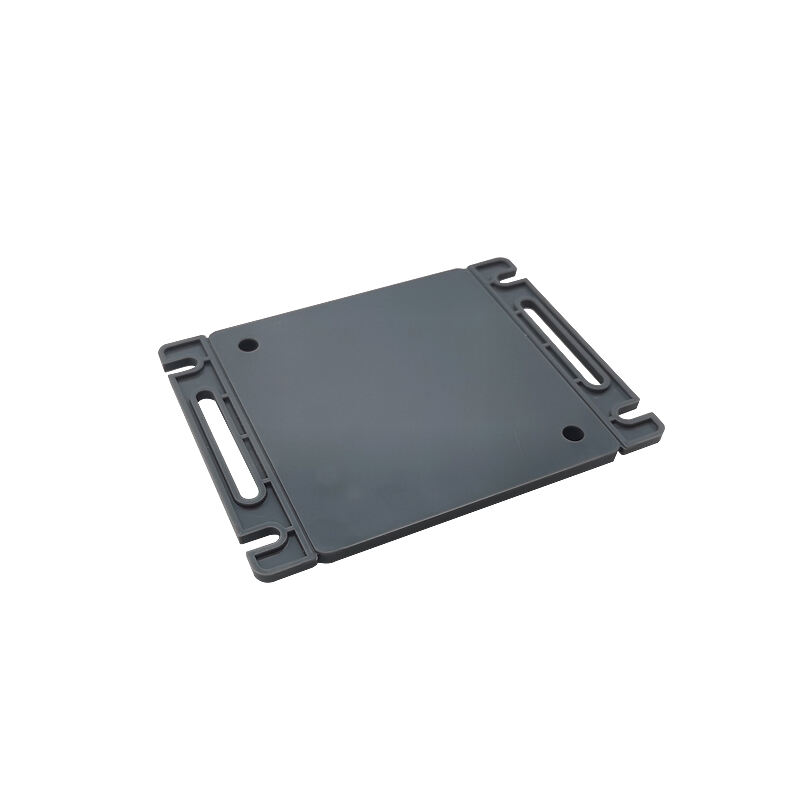

plastic injection molding

Plastic injection molding is a revolutionary manufacturing process that transforms raw plastic materials into precise, complex parts through a sophisticated mechanism of heating, injecting, and cooling. This versatile technology operates by melting plastic pellets and forcefully injecting the molten material into a custom-designed mold cavity. The process begins when plastic granules are fed into a heated barrel where they are melted to achieve a consistent viscosity. The molten plastic is then injected under high pressure into the mold, where it fills every cavity and detail. As the material cools and solidifies, it takes on the exact shape of the mold, including intricate features and textures. The completed part is then ejected, and the cycle begins again. This highly efficient process enables the production of thousands of identical parts with exceptional accuracy and consistency. The technology accommodates a wide range of plastics, from common thermoplastics to high-performance engineering materials, making it suitable for numerous applications across industries including automotive, medical, consumer goods, and electronics. Modern injection molding machines are equipped with advanced controls and monitoring systems that ensure precise temperature regulation, pressure control, and timing parameters, resulting in superior quality products with minimal waste.