Design Flexibility and Material Innovation

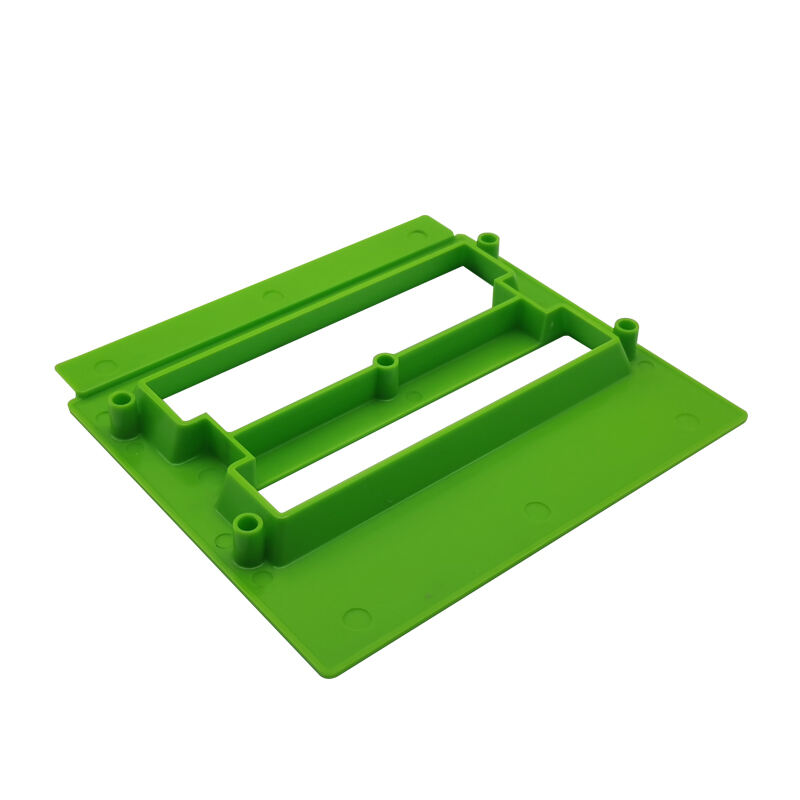

The remarkable design flexibility offered by injection molding opens up countless possibilities for product development and innovation. Engineers can incorporate various design elements such as snap fits, living hinges, threads, and textured surfaces directly into the molded part. This capability, combined with advanced material science, allows for the creation of parts with specific mechanical, thermal, and electrical properties. Modern injection molding supports the use of innovative materials, including high performance polymers, fiber reinforced composites, and specialized alloys. The process accommodates both simple and intricate designs, enabling the production of parts ranging from basic components to highly complex assemblies with multiple integrated functions.