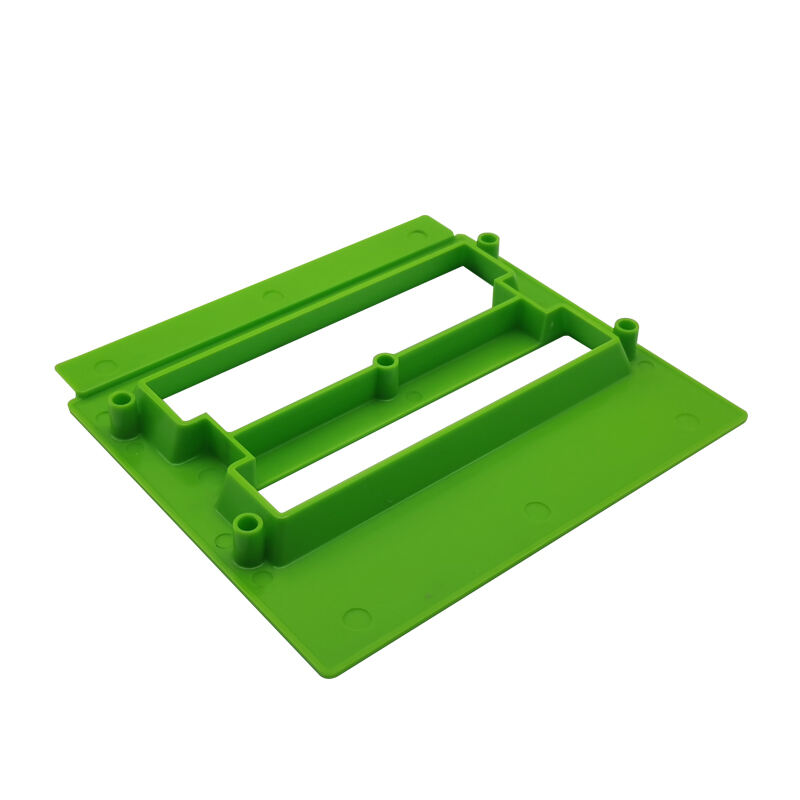

plastic injection service

Plastic injection service represents a sophisticated manufacturing process that transforms raw plastic materials into precisely engineered products through a carefully controlled injection molding system. This advanced manufacturing method involves heating plastic pellets to their melting point, then injecting the molten material into custom-designed molds under high pressure. The process accommodates a wide range of thermoplastic and thermosetting materials, enabling the production of components with complex geometries and intricate details. The service encompasses comprehensive solutions, from initial design consultation and prototype development to full-scale production runs. State-of-the-art injection molding machines, equipped with precision control systems, ensure consistent quality across production batches. The technology allows for the integration of various features such as threads, snap-fits, and living hinges directly into the molded parts, eliminating the need for secondary operations. This service is particularly valuable across numerous industries, including automotive, consumer electronics, medical devices, and household products, offering scalable production capabilities from small runs to high-volume manufacturing. The process also incorporates advanced quality control measures, utilizing computer-aided design (CAD) and simulation software to optimize part design and minimize potential manufacturing issues before production begins.