The principles of heat dissipation are crucial in managing thermal output in electronics, encompassing conduction, convection, and radiation. Conduction involves the direct transfer of heat through a material, convection refers to heat transfer via fluid movements (like air or liquid), and radiation involves heat transfer through electromagnetic waves. Aluminum heat sinks play a pivotal role in enhancing these cooling processes, particularly by increasing the surface area exposed to airflow, thus facilitating efficient heat dissipation in electronic devices. The numerous fins and porous structures of aluminum heat sinks make them particularly effective as they disperse heat quickly into the surrounding environment.

Research underscores the efficacy of aluminum heat sinks in improving thermal management within electronic devices. For instance, empirical studies have demonstrated that aluminum heat sinks can lower operating temperatures significantly, thereby increasing the lifespan and reliability of the devices they cool. By integrating this material, device designers can ensure that electronic components operate within optimal temperature ranges, safeguarding against overheating and subsequent hardware failures.

Convection plays a significant role in the cooling performance of aluminum heat sinks, utilizing fluid movement to transfer heat away from electronic components. The design of these heat sinks often pivots on optimizing this process, whether through natural or forced convection. Natural convection relies on the buoyancy of heated air to rise and be replaced by cooler air, while forced convection enhances this effect using fans or blowers to increase airflow across the heat sink. This distinction is vital for designing effective thermal management systems; for instance, forced convection is commonly employed in systems requiring higher cooling efficiency.

Studies have shown that optimized convection in aluminum heat sinks can lead to substantial improvements in thermal performance. For example, experimental data indicate that implementing forced convection can reduce operating temperatures markedly compared to natural convection scenarios. By refining these convection processes and designs, manufacturers can significantly elevate the cooling capabilities of aluminum heat sinks, ensuring that high-performance electronic devices maintain their function even under intensive operational conditions.

When comparing aluminum to metals like copper for heat sink applications, aluminum is notably less thermally conductive, with a thermal conductivity of around 230 W/m-K compared to copper's 390 W/m-K. However, aluminum is frequently favored due to its significant advantages in weight and cost, making it more practical for many applications despite its lower thermal conductivity. For instance, aluminum is roughly one-third the weight of copper, which can be critical in applications where weight reduction is crucial. Moreover, industry experts often choose aluminum for electronic devices due to its ease of manufacturing and affordability, allowing for efficient cooling solutions without the added expenses associated with materials like copper.

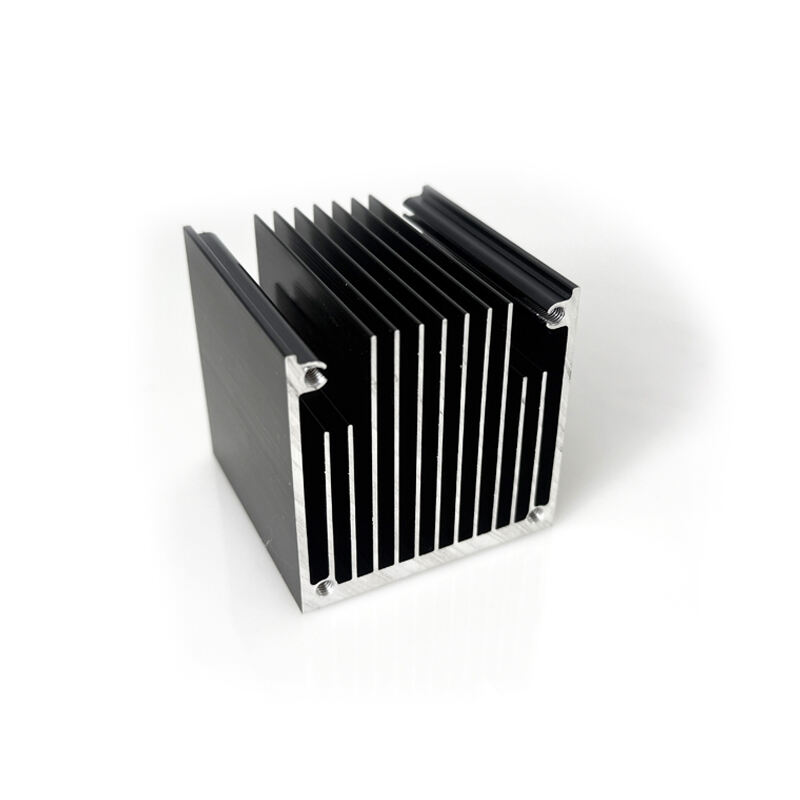

Aluminum heat sinks employ several mechanisms to efficiently transfer heat, primarily through conduction and convection. Conduction involves the direct transfer of heat through the aluminum, while convection facilitates the movement of heat away from the heat sink surface through airflow. Surface treatments such as anodizing can significantly enhance heat transfer by increasing the surface area and improving thermal conductivity. Data supports that optimized designs incorporating these treatments can lead to superior heat transfer rates, demonstrating their effectiveness in thermal management. For instance, detailed case studies have shown that anodized aluminum heat sinks can achieve up to a 20% increase in cooling efficiency compared to untreated counterparts.

One of the primary advantages of aluminum when utilized in heat sinks is its lightweight nature, which simplifies handling and installation considerably. This lightweight property reduces transportation costs and installation efforts, making aluminum the go-to choice for manufacturers and technicians alike. Furthermore, lighter heat sinks alleviate mechanical stress on electronic components, enhancing device longevity by minimizing potential damage from excessive weight. This is particularly beneficial in portable electronic gadgets where maintaining low weight without compromising performance is crucial.

Industry experts highlight the balance between weight and performance as a pivotal factor in selecting materials for heat sinks. Aluminum, with its optimal ratio of weight to thermal performance, often surpasses heavier metals that may offer marginally better heat dissipation at the cost of increased stress and complexity in design. This makes it a preferred choice in many applications, including consumer electronics and computing devices, where both performance and reliability weigh heavily on design decisions.

Aluminum's durability in high-temperature environments is another key factor making it ideal for heat sinks. Unlike other materials that may lose structural integrity or degrade when exposed to continuous high temperatures, aluminum maintains its form and function. Specific aluminum alloys are designed to excel even under extreme conditions, ensuring the reliability of the heat sink over prolonged periods. This is critical in scenarios where devices are exposed to intense heat, as in industrial electronics or high-performance computing.

Studies comparing various materials show that aluminum heat sinks typically have enhanced lifespans and lower failure rates in elevated temperature settings compared to alternative materials. This resilience not only prevents component failure but also extends the device's operational life, offering both economic and practical benefits. This durability, combined with high thermal efficiency, positions aluminum as a top choice for industries aiming for cost-effective and reliable thermal management solutions.

Aluminum heat sinks are renowned for their cost-effectiveness in mass production, primarily due to aluminum's abundant availability and lower processing costs compared to other materials like copper. The extrusion process for aluminum is more economical, leading to substantial savings for manufacturers when scaling production volumes. Moreover, aluminum's lightweight properties contribute to reduced transportation costs, further enhancing its appeal for large-scale production. Industry reports highlight that aluminum heat sinks offer significant economies of scale, allowing manufacturers and businesses to optimize production costs while maintaining high quality. These cost savings have been increasingly evident in sectors such as consumer electronics, where price sensitivity is critical, and aluminum's competitive edge continues to thrive.

Aluminum offers remarkable flexibility in producing heat sinks of various shapes and sizes, a crucial advantage for meeting specific design requirements and customization needs. Due to its malleability, manufacturers can easily adjust the design and dimensions of aluminum heat sinks, supporting diverse electronic configurations. Additionally, the scalability of aluminum heat sinks enables manufacturers to increase or decrease production volumes without substantial retooling, which is critical for responding to shifting market demands. Various successful product lines in the automotive and telecommunications industries, such as those using pin fin configurations, exemplify the successful application of customizable aluminum heat sinks. This adaptability not only helps meet specific client needs but also supports efficient inventory management, enhancing operational flexibility across production scales.

Anodizing significantly enhances the corrosion resistance of aluminum heat sinks, making them more reliable and longer-lasting. The process involves electrochemically treating the aluminum surface to form a protective oxide layer, which increases durability, especially in harsh environments like marine or industrial settings. This oxide layer acts as a barrier against corrosive elements, preventing wear and tear over time. Studies have consistently shown that anodized aluminum outperforms untreated aluminum in resisting degradation, with significant longevity benefits captured in environmental exposure tests. By making aluminum heat sinks more robust, anodizing ensures they maintain peak performance throughout their lifespan, even under demanding operational conditions.

Anodizing does more than just boost durability; it also improves the thermal emissivity of aluminum heat sinks. This treatment enhances their ability to dissipate heat efficiently, crucial in preventing thermal runaway and component failure in electronics. The anodized surface increases heat dissipation by facilitating a better convection process, helping maintain optimal operating temperatures for electronic components. Empirical data underscores this benefit, with anodized aluminum heat sinks showing marked improvements in cooling efficiency compared to their non-treated counterparts. By optimizing the heat dissipation capabilities, anodizing contributes to the superior thermal performance of heat sinks, ensuring electronic systems run cooler and more reliably.

Aluminum heat sinks are generally preferred over copper due to their lightweight, cost-effectiveness, and ease of manufacturing, which outweigh the slightly lower thermal conductivity compared to copper. This makes them ideal for applications where weight reduction and affordability are crucial.

Anodizing enhances aluminum heat sinks by increasing their corrosion resistance and thermal emissivity, thus improving their durability and heat dissipation efficiency.

Convection helps aluminum heat sinks in transferring heat away from electronic components. It can be natural or forced, with forced convection providing higher efficiency by utilizing fans or blowers to enhance airflow.