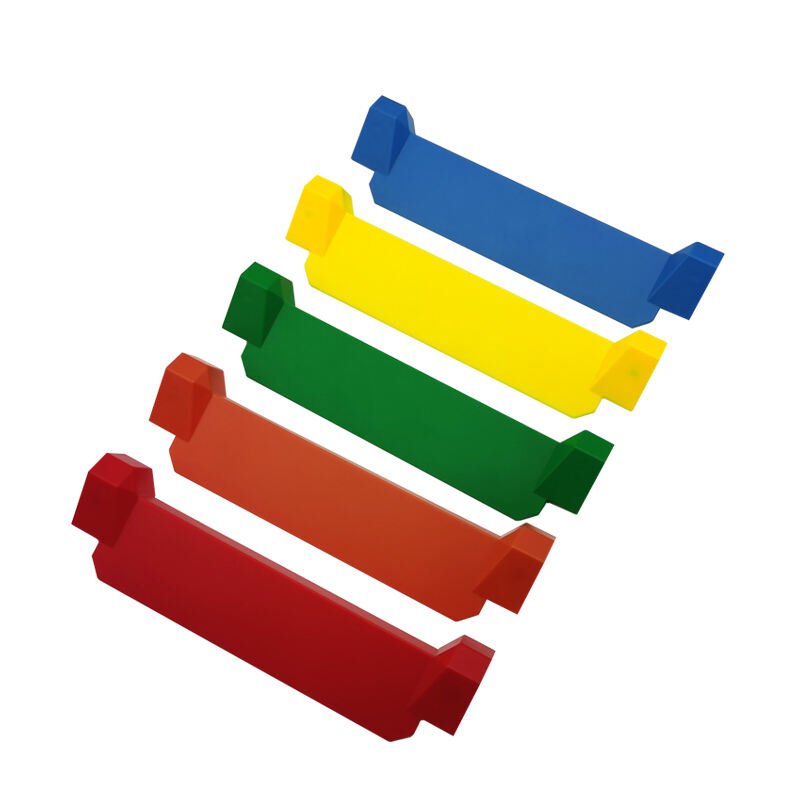

injection molded plastic parts

Injection molded plastic parts represent a cornerstone of modern manufacturing, offering unprecedented versatility and precision in producing complex components. This manufacturing process involves injecting molten plastic material into a custom-designed mold cavity under high pressure, where it cools and solidifies into the desired shape. The technology enables the production of parts ranging from microscopic components for medical devices to large automotive panels. Advanced injection molding systems incorporate sophisticated controls for temperature, pressure, and timing, ensuring consistent quality across production runs. The process accommodates a wide variety of thermoplastic and thermosetting polymers, each selected based on specific application requirements such as mechanical strength, chemical resistance, or thermal stability. Modern injection molding machines feature computer-controlled operations, allowing for precise adjustments and monitoring of critical parameters throughout the manufacturing cycle. This technology has revolutionized product development by enabling rapid prototyping and efficient mass production, while maintaining high quality standards and reducing material waste.