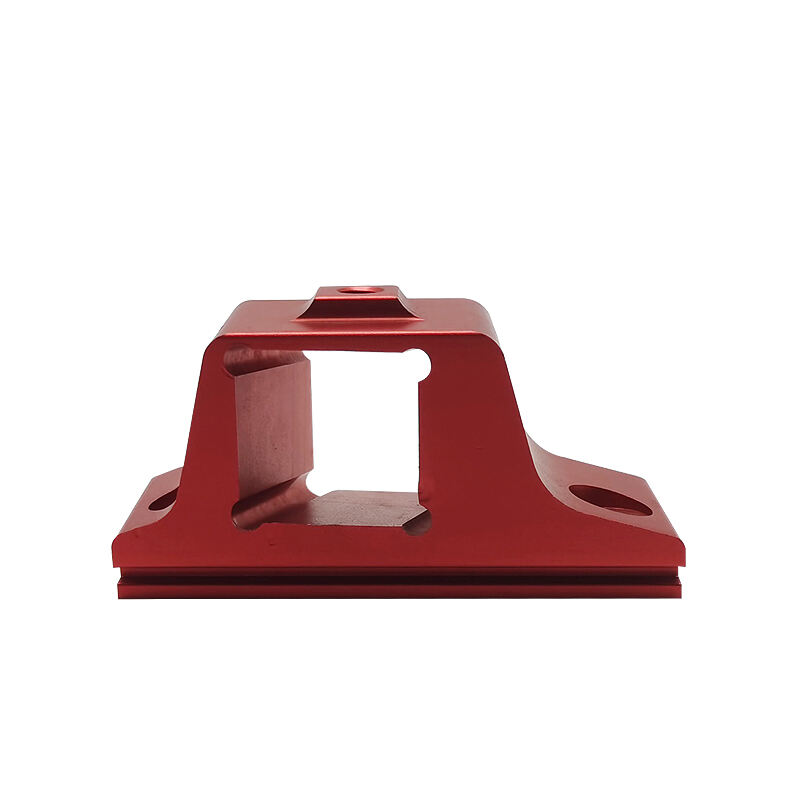

cnc turned parts

CNC turned parts represent a cornerstone of modern manufacturing precision, produced through Computer Numerical Control (CNC) turning processes that transform raw materials into highly accurate components. These parts are crafted by rotating the workpiece while cutting tools remove material to create the desired shape with exceptional precision, typically achieving tolerances as tight as ±0.0005 inches. The process excels in producing cylindrical, conical, and complex geometrical shapes, making it ideal for manufacturing components like shafts, pins, bolts, and custom mechanical parts. Modern CNC turning centers incorporate advanced features such as live tooling, multiple spindles, and automated tool changers, enabling the production of intricate features including threads, grooves, and various surface patterns. The technology employs sophisticated computer programming to ensure consistent quality across large production runs, while maintaining the flexibility to accommodate small batch orders. These parts find extensive applications across industries including aerospace, automotive, medical devices, and precision instruments, where dimensional accuracy and surface finish quality are paramount.