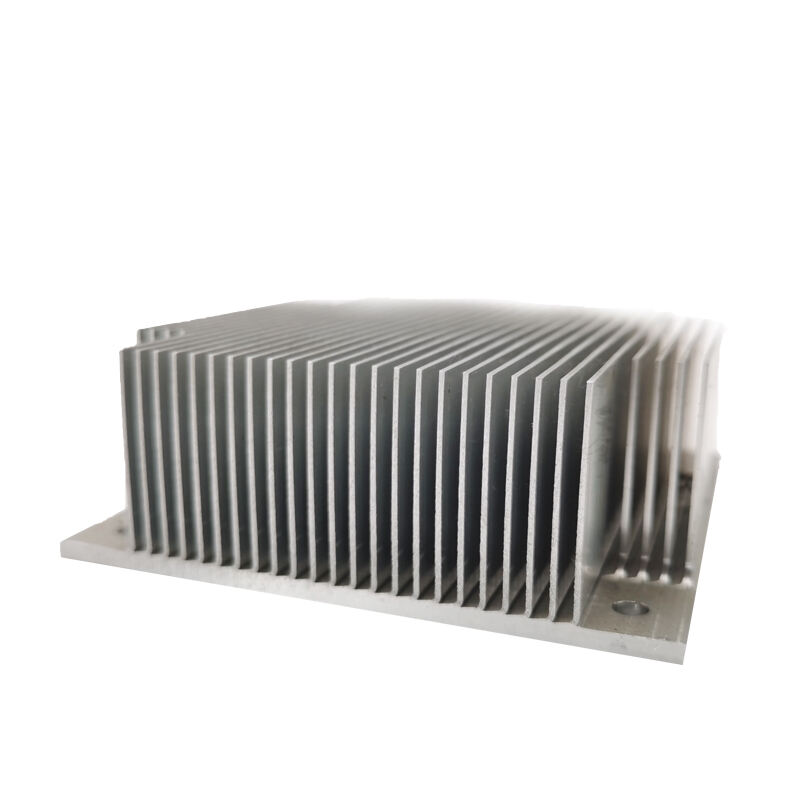

anodized heat sink

An anodized heat sink represents a crucial advancement in thermal management technology, combining superior heat dissipation with enhanced durability through the anodization process. This specialized component features a protective oxide layer that significantly improves corrosion resistance while maintaining excellent thermal conductivity. The manufacturing process involves treating aluminum or other metal surfaces electrochemically, creating a robust outer layer that protects against environmental factors while optimizing heat transfer capabilities. These heat sinks are engineered with precision-designed fins or pins that maximize surface area for heat dissipation, allowing for efficient cooling in various applications. The anodized surface treatment not only enhances the aesthetic appeal with various color options but also provides a harder, more wear-resistant surface compared to non-anodized alternatives. The microscopic pore structure created during anodization facilitates better thermal interface material adhesion, improving overall thermal performance. In industrial applications, these heat sinks prove invaluable in maintaining optimal operating temperatures for electronic components, power supplies, LED lighting systems, and high-performance computing equipment.