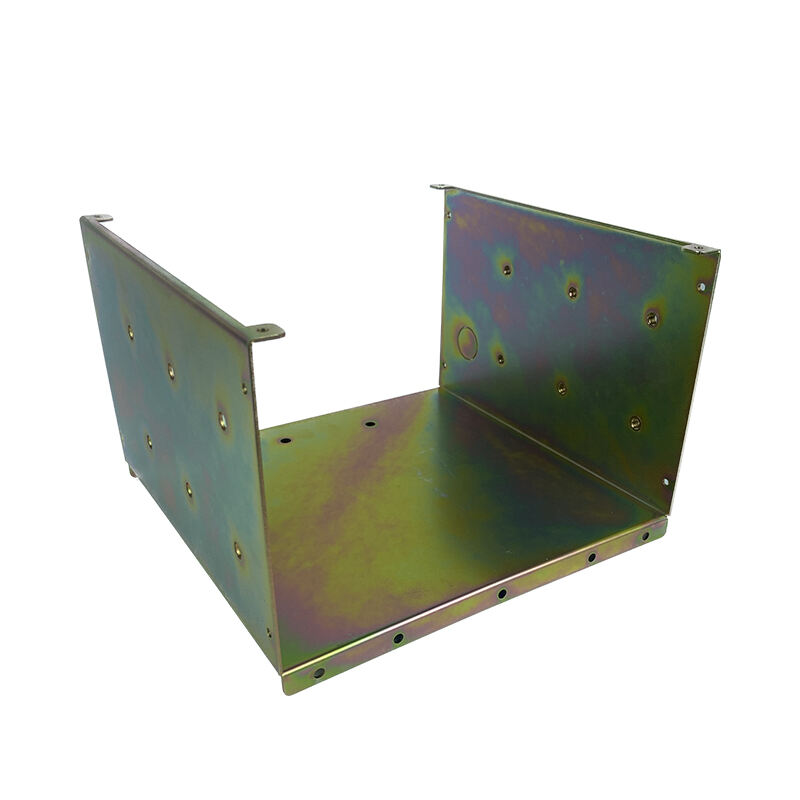

stainless steel sheet metal fabrication

Stainless steel sheet metal fabrication is an advanced manufacturing process that transforms flat stainless steel sheets into customized components and products. This versatile process combines precision engineering with modern fabrication techniques to create durable, corrosion-resistant parts for various industries. The process typically involves cutting, forming, welding, and finishing operations, all performed with high-precision machinery and skilled craftsmanship. Modern fabrication facilities employ sophisticated technologies such as CNC laser cutting, precision brake forming, and automated welding systems to ensure consistent quality and tight tolerances. The fabrication process can accommodate various stainless steel grades, including 304, 316, and 430, each offering specific properties suited to different applications. This manufacturing method is particularly valued in industries requiring sanitary conditions, such as food processing, pharmaceutical manufacturing, and medical equipment production. The versatility of stainless steel sheet metal fabrication allows for the creation of everything from simple brackets and enclosures to complex architectural elements and industrial equipment components. The process can handle projects of varying scales, from small prototype runs to large-scale production, while maintaining consistent quality and dimensional accuracy throughout.