sheet metal production

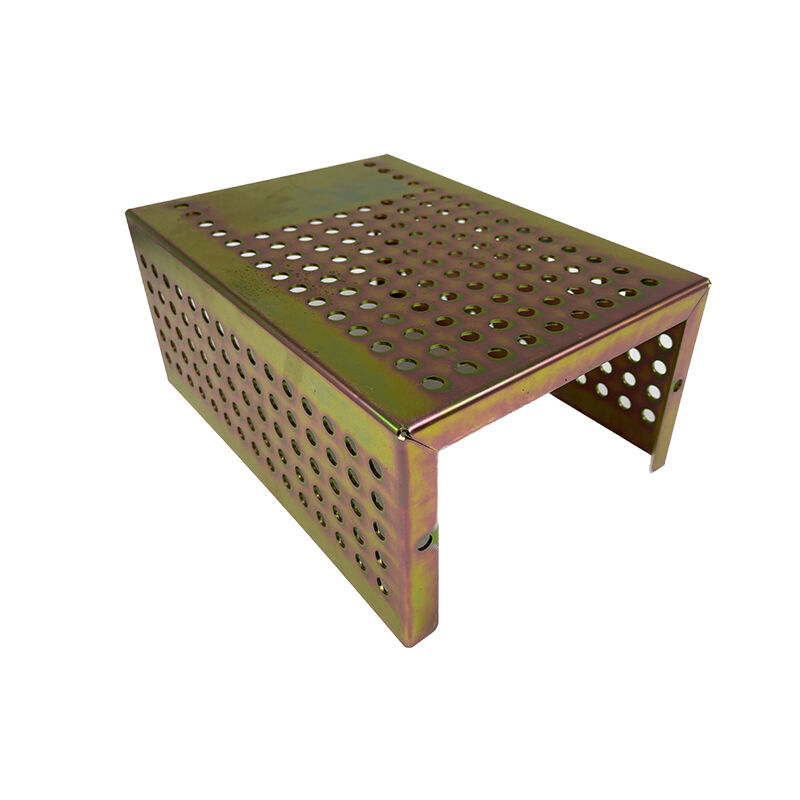

Sheet metal production is a sophisticated manufacturing process that transforms flat metal sheets into functional components through various forming techniques. This versatile process encompasses cutting, bending, punching, and forming operations to create precise metal parts for diverse industries. Modern sheet metal production utilizes advanced CNC machinery and CAD/CAM systems, enabling manufacturers to achieve tight tolerances and complex geometries. The process begins with material selection, where metals like steel, aluminum, or copper are chosen based on specific application requirements. These materials undergo careful preparation, including deburring and surface treatment, before being processed through state-of-the-art equipment. Sheet metal production supports both prototype development and high-volume manufacturing, making it essential for industries ranging from automotive and aerospace to electronics and construction. The process excels in creating components such as enclosures, brackets, panels, and structural elements while maintaining cost-effectiveness through minimal material waste and efficient production methods. Quality control measures, including dimensional inspection and material testing, ensure consistent product quality throughout the manufacturing cycle.