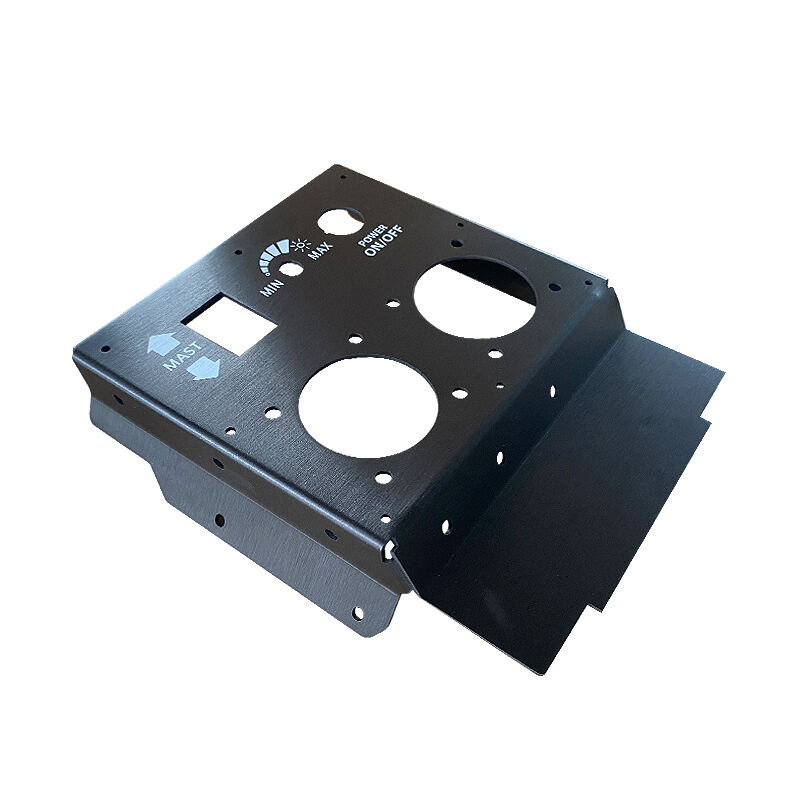

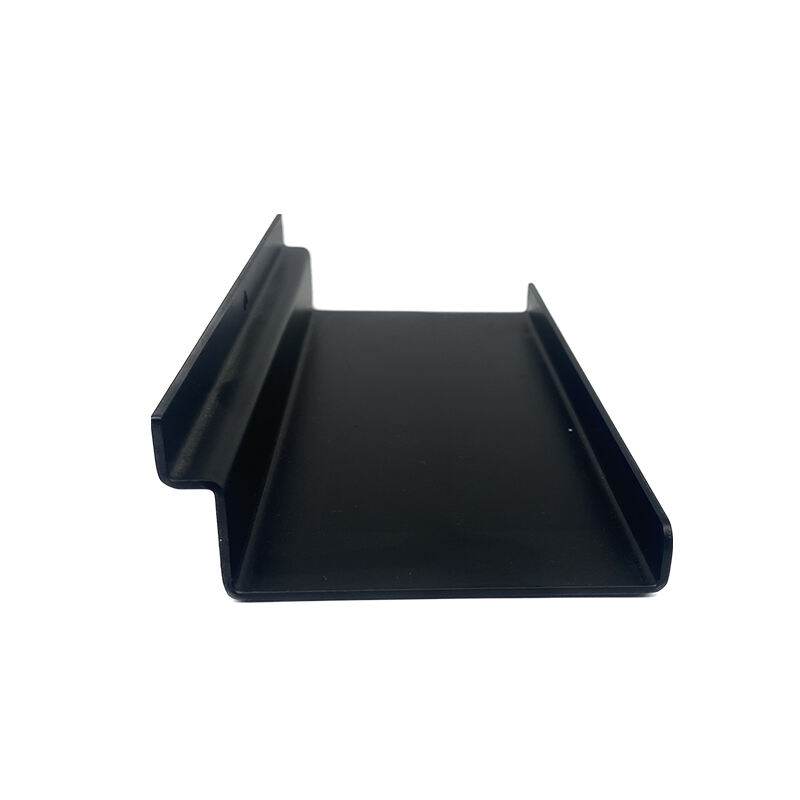

custom sheet metal fabrication

Custom sheet metal fabrication is a sophisticated manufacturing process that transforms flat metal sheets into precise, functional components through various operations. This versatile process encompasses cutting, bending, punching, and welding techniques to create custom parts that meet specific design requirements. Modern sheet metal fabrication facilities utilize advanced CNC machinery and CAD/CAM technology to ensure exceptional accuracy and repeatability in production. The process begins with design optimization, where engineers analyze material properties and manufacturing constraints to create cost-effective solutions. State-of-the-art laser cutting and precision forming equipment enable the creation of complex geometries while maintaining tight tolerances. This manufacturing method serves diverse industries, including aerospace, automotive, electronics, and architectural applications. The ability to work with various materials, from aluminum and steel to specialty alloys, makes custom sheet metal fabrication invaluable for both prototype development and high-volume production runs. The process also incorporates quality control measures at every stage, from material selection to final assembly, ensuring that each component meets stringent specifications and industry standards.