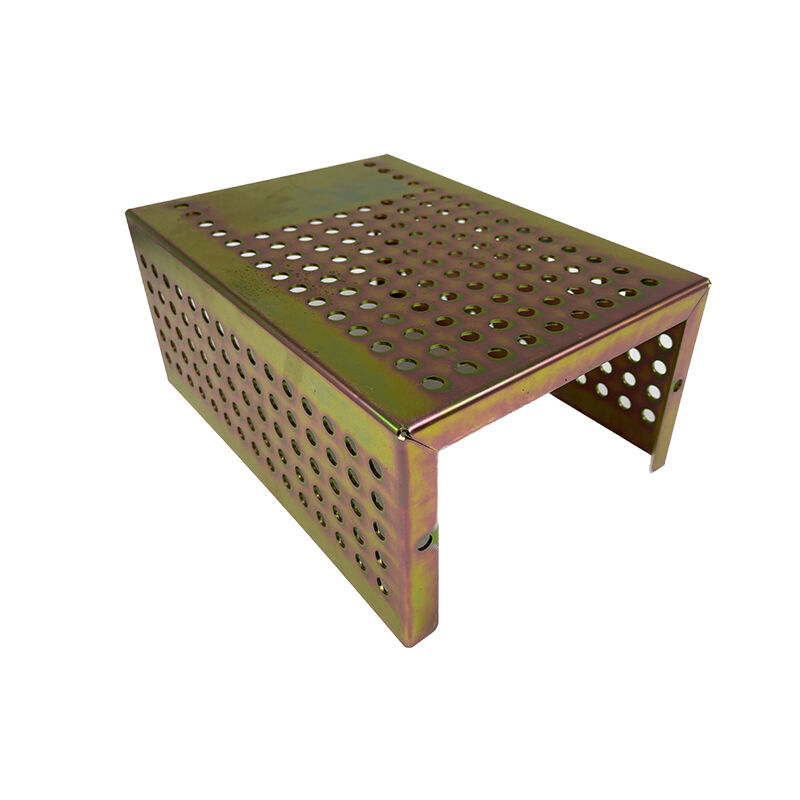

sheet metal stamping parts

Sheet metal stamping parts represent a cornerstone of modern manufacturing, offering precision-engineered components through a sophisticated process of shaping flat metal sheets. This manufacturing technique employs specialized tools and dies to transform metal sheets into specific shapes and designs through various operations including punching, bending, and forming. The process is highly versatile, capable of producing both simple and complex geometries with exceptional accuracy and consistency. Sheet metal stamping operates across multiple scales, from micro-components used in electronics to larger automotive body panels. The technology incorporates advanced automation systems and quality control measures to ensure dimensional accuracy and surface finish quality. These parts are fundamental to numerous industries, including automotive manufacturing, aerospace applications, consumer electronics, and industrial machinery. The process excels in high-volume production scenarios, offering cost-effective solutions while maintaining precise tolerances and material integrity. Modern sheet metal stamping incorporates progressive die systems, enabling multiple operations to be performed in sequence, significantly improving production efficiency and part consistency. The versatility of this manufacturing method allows for the use of various materials, including steel, aluminum, copper, and brass, each selected based on specific application requirements.