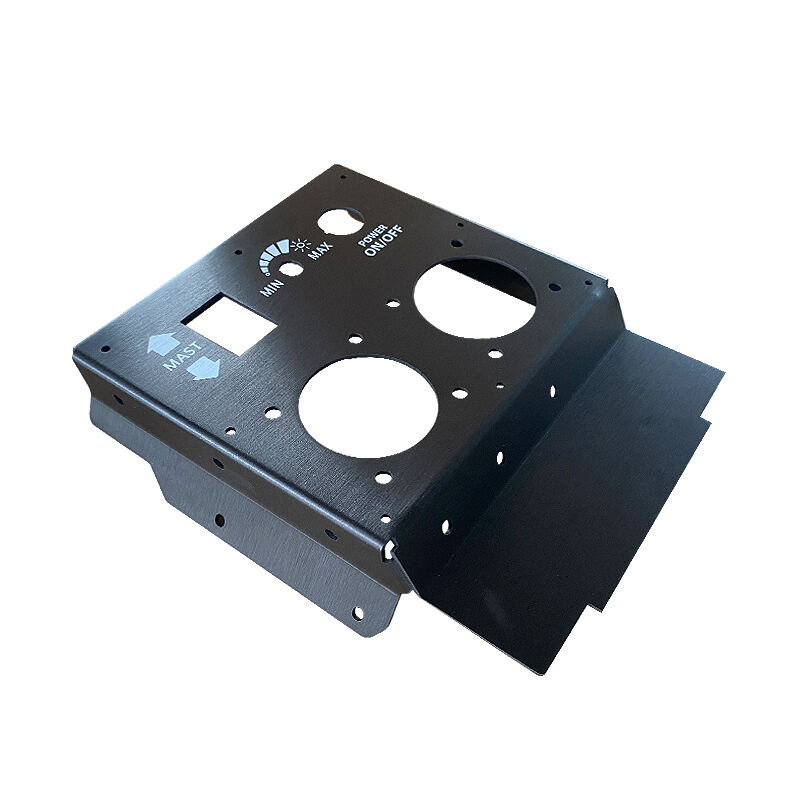

sheet metal parts

Sheet metal parts represent a cornerstone of modern manufacturing, offering versatile solutions for various industrial applications. These precision-engineered components are produced through sophisticated processes including cutting, bending, stamping, and forming of metal sheets into specific shapes and configurations. The manufacturing process typically begins with flat metal sheets of varying thicknesses, which are then transformed using advanced CNC machinery and specialized tooling. These parts are essential in industries ranging from automotive and aerospace to electronics and construction. The technological advancement in sheet metal fabrication has enabled manufacturers to achieve unprecedented levels of accuracy and consistency, with tolerances often measured in micrometers. Modern sheet metal parts incorporate features such as complex geometries, integrated mounting points, and specialized surface treatments that enhance their functionality and durability. The materials used can vary from standard steel and aluminum to specialized alloys, each selected based on specific application requirements such as strength, weight, corrosion resistance, and thermal conductivity. The versatility of sheet metal parts allows for both high-volume production runs and custom, small-batch manufacturing, making them an ideal solution for diverse industrial needs.