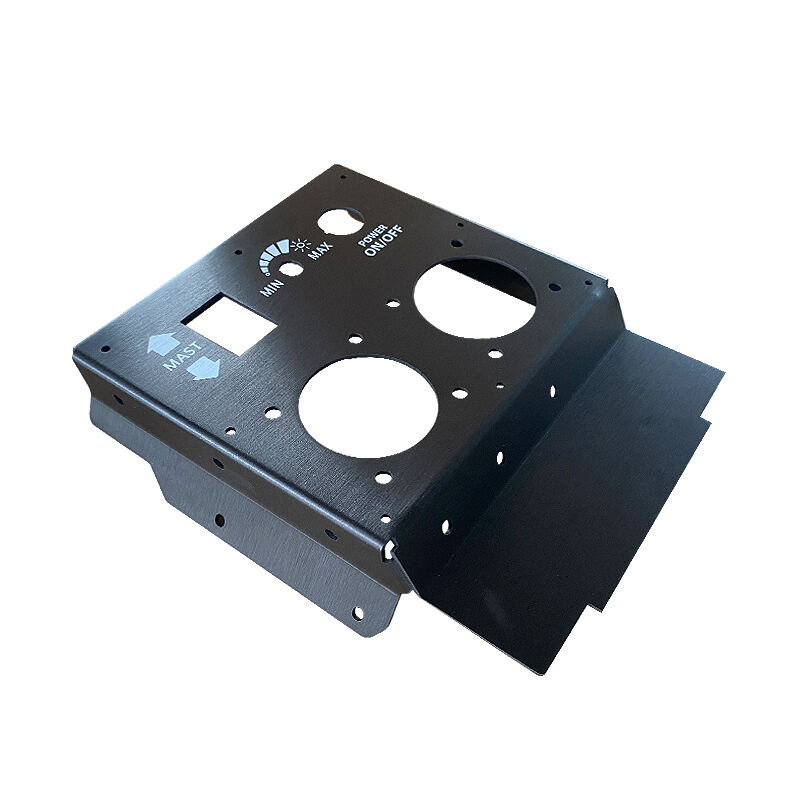

laser cutting parts

Laser cutting parts represent a pinnacle of modern manufacturing precision, offering unparalleled accuracy in the creation of complex components across various industries. This advanced technology utilizes focused laser beams to cut materials with exceptional precision, creating clean edges and intricate designs that would be difficult or impossible to achieve through traditional cutting methods. The process involves sophisticated computer numerical control (CNC) systems that guide the laser beam along predetermined paths, ensuring consistent quality and reproducibility. These parts are manufactured using state of the art equipment that can handle diverse materials including metals, plastics, wood, and composites, making them versatile for multiple applications. The technology enables the production of components with tolerances as tight as 0.1mm, suitable for aerospace, automotive, medical device manufacturing, and electronic industries. The process is highly automated, reducing human error while maintaining superior quality standards across production runs. Additionally, laser cutting parts can be customized to meet specific requirements, offering flexibility in design modifications and rapid prototyping capabilities.