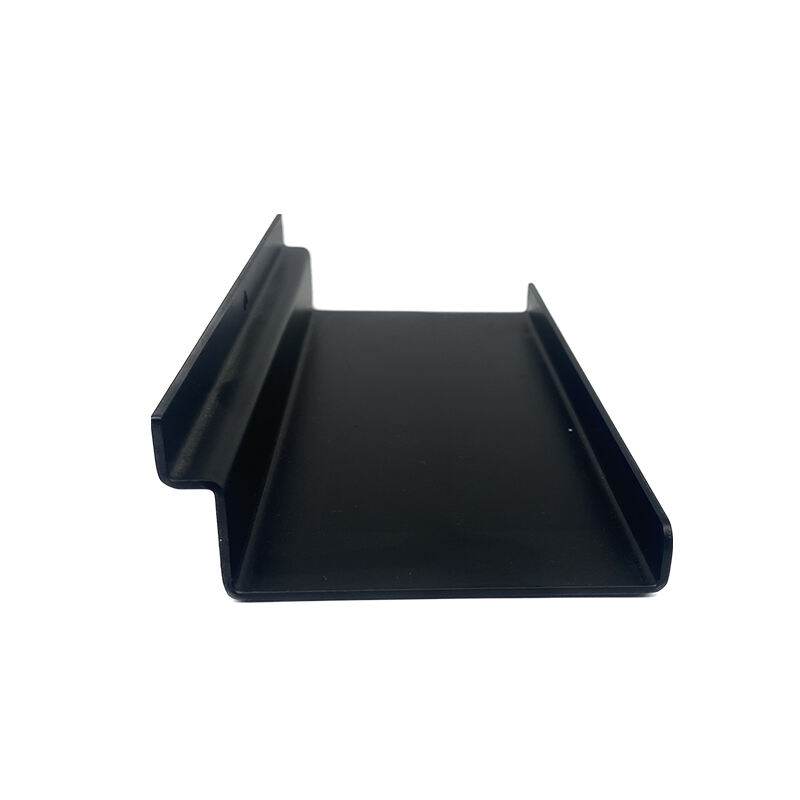

aluminium sheet metal fabrication

Aluminium sheet metal fabrication is a sophisticated manufacturing process that transforms raw aluminium sheets into diverse components and products through various techniques including cutting, forming, and joining. This versatile process combines precision engineering with modern technology to create both standard and custom parts for multiple industries. The process begins with high-quality aluminium sheets, which are then subjected to various fabrication methods such as laser cutting, punching, bending, and welding. Modern CNC machinery ensures exceptional accuracy and repeatability in the fabrication process, while advanced CAD/CAM systems enable complex designs to be realized with precision. The lightweight yet durable nature of aluminium makes it an ideal material for fabrication, offering excellent corrosion resistance and strength-to-weight ratio. Applications range from aerospace components and automotive parts to architectural elements and consumer products. The process accommodates both small-scale prototypes and large-volume production runs, making it suitable for various business needs. The flexibility of aluminium sheet metal fabrication allows for customization in thickness, size, and finish, while maintaining consistent quality and dimensional accuracy throughout the production process.