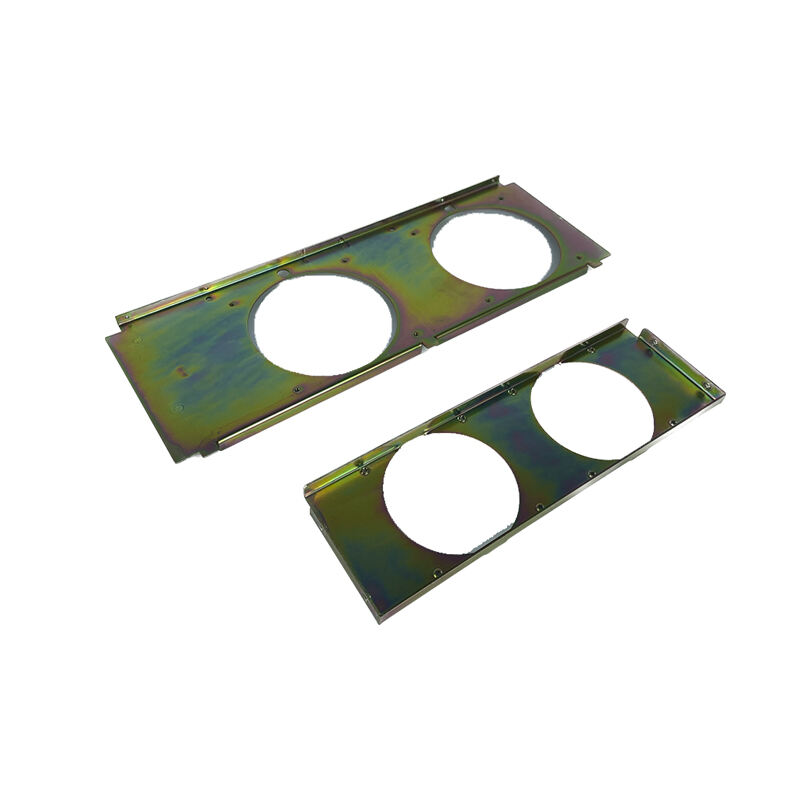

sheet metal fabrication products

Sheet metal fabrication products represent a cornerstone of modern manufacturing, combining precision engineering with versatile applications across multiple industries. These products are created through sophisticated processes including cutting, bending, punching, and welding of metal sheets into specific shapes and components. Modern sheet metal fabrication employs advanced CNC technology and automated systems to ensure exceptional accuracy and consistency in production. The products range from simple brackets and enclosures to complex assemblies used in aerospace, automotive, and electronics industries. What sets these products apart is their ability to maintain structural integrity while offering customizable solutions for various applications. The fabrication process allows for the creation of products with precise tolerances, typically ranging from 0.1 to 0.5 millimeters, ensuring perfect fit and functionality. These products can be manufactured using various materials including stainless steel, aluminum, copper, and brass, each chosen for specific properties such as corrosion resistance, conductivity, or strength-to-weight ratio. The versatility of sheet metal fabrication enables the production of both prototype quantities and high-volume runs, making it an ideal solution for businesses of all sizes.