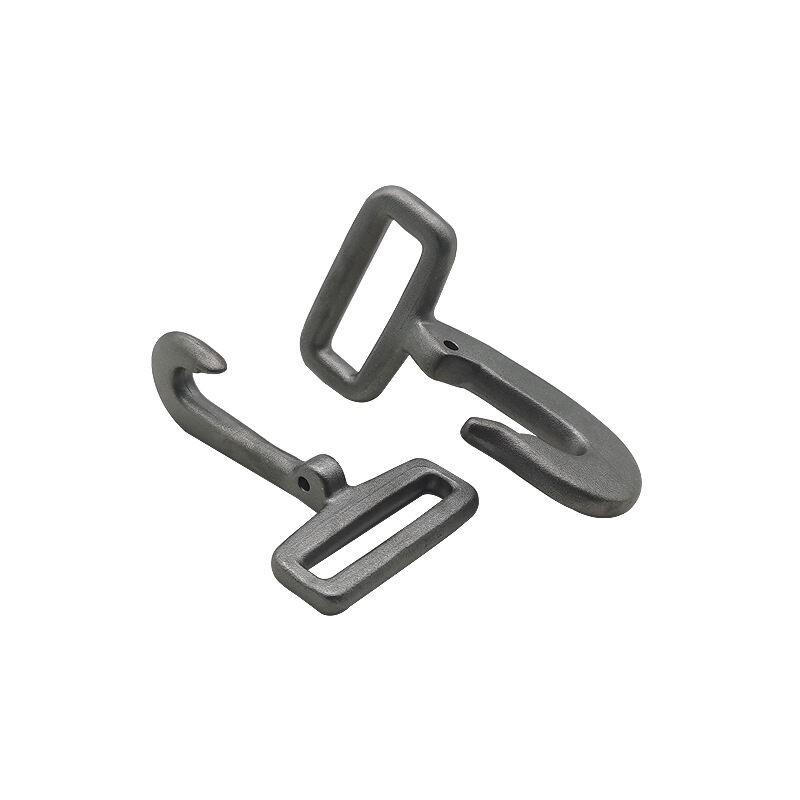

iron casting

Iron casting represents a fundamental manufacturing process that has been refined over centuries to create durable, complex metal components. This versatile method involves pouring molten iron into precisely engineered molds, allowing manufacturers to produce parts ranging from simple brackets to intricate machinery components. The process begins with carefully selected raw materials, including iron, carbon, and various alloying elements, which are melted in furnaces at temperatures exceeding 2,500 degrees Fahrenheit. Modern iron casting incorporates advanced technologies such as computer-aided design (CAD) and simulation software to optimize mold design and metal flow patterns, ensuring consistent quality and minimal defects. The process accommodates various iron grades, including gray iron, ductile iron, and white iron, each offering specific properties suited to different applications. This manufacturing method proves particularly valuable in industries such as automotive, construction, agriculture, and heavy machinery, where strength, wear resistance, and cost-effectiveness are crucial factors. The versatility of iron casting allows for the production of components with varying wall thicknesses, intricate geometries, and specific mechanical properties, making it an indispensable process in modern manufacturing.