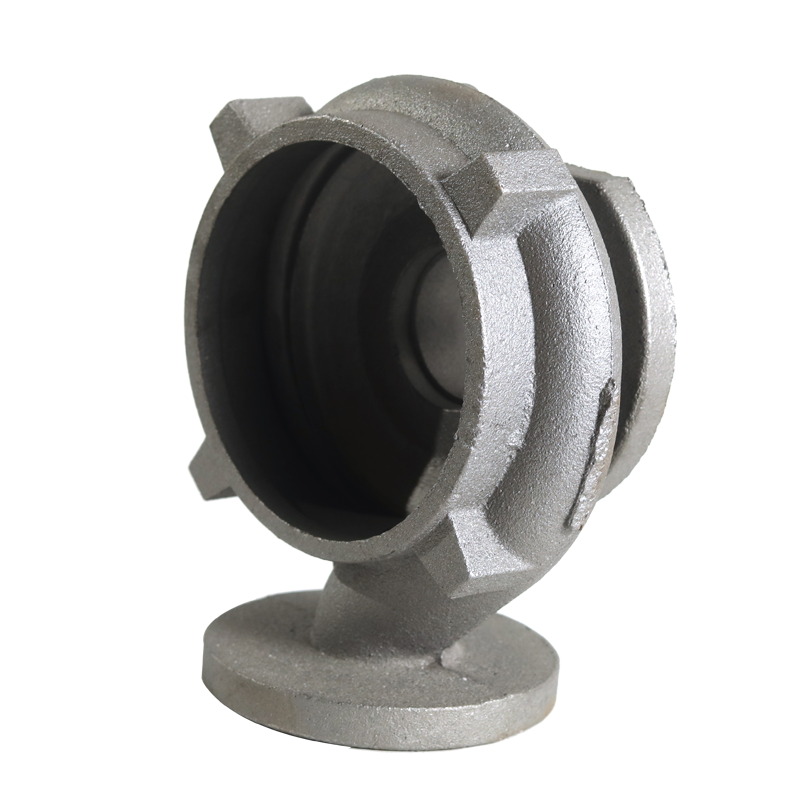

custom casting parts

Custom casting parts represent a cornerstone of modern manufacturing, offering tailored solutions for diverse industrial applications. These precision-engineered components are produced through specialized casting processes that allow for intricate designs and complex geometries that would be difficult or impossible to achieve through other manufacturing methods. The process begins with creating detailed molds based on customer specifications, followed by pouring molten metal or alloys into these precisely crafted cavities. The versatility of custom casting extends across various materials, including steel, aluminum, brass, and iron, enabling manufacturers to select the optimal material for specific performance requirements. Advanced technologies such as computer-aided design (CAD) and simulation software ensure exceptional accuracy and repeatability in the production process. These parts find extensive applications in automotive, aerospace, medical equipment, and heavy machinery industries. The ability to incorporate specific design features, such as internal channels, varying wall thicknesses, and complex surface textures, makes custom casting parts invaluable for specialized equipment and machinery. Modern casting facilities employ state-of-the-art quality control measures, including dimensional inspection, material testing, and non-destructive evaluation techniques to ensure each part meets exact specifications.