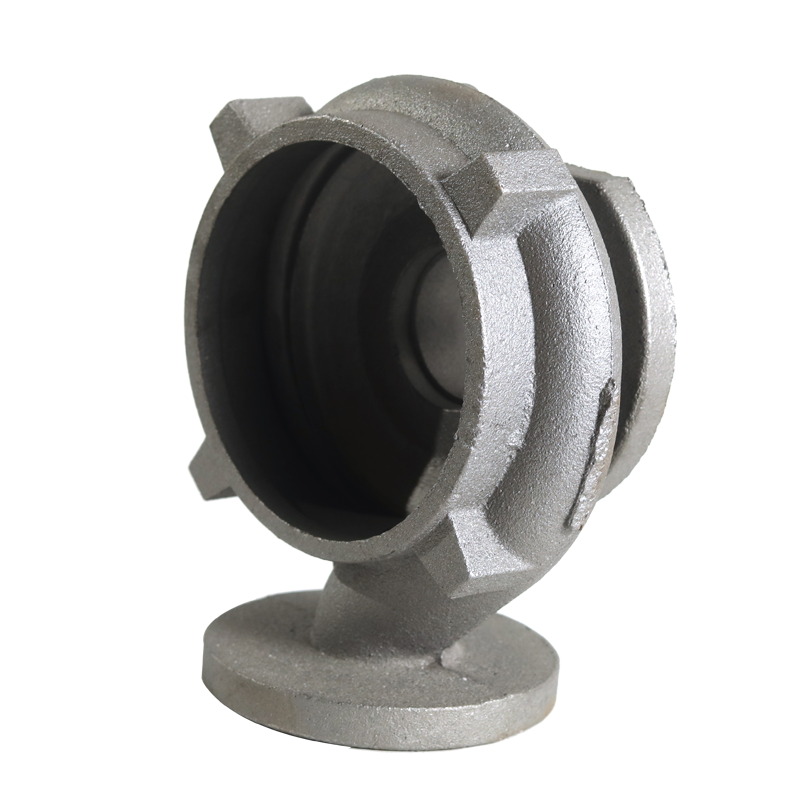

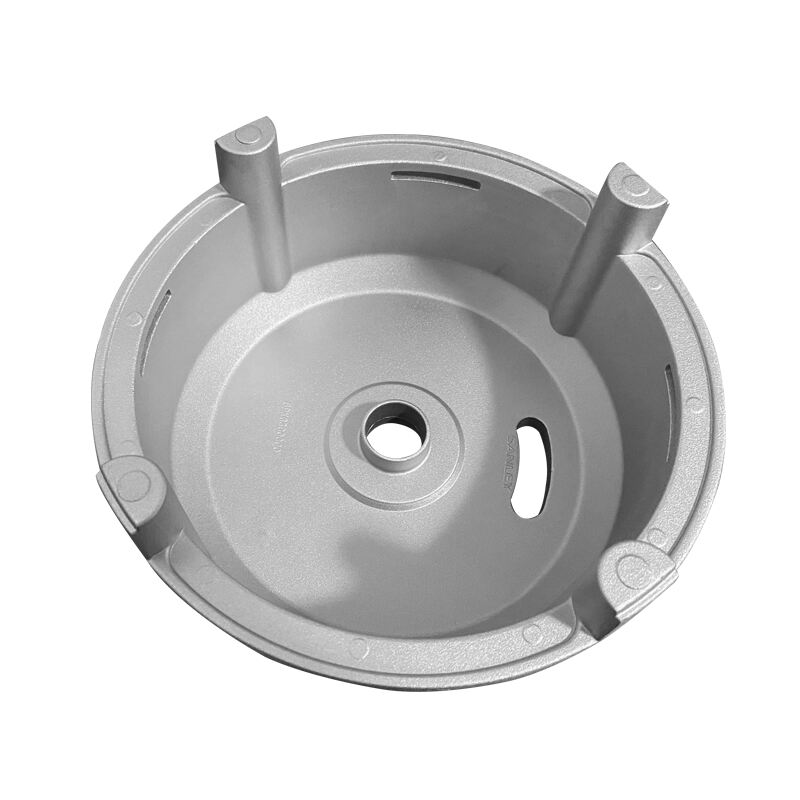

aluminium die casting parts

Aluminum die casting parts represent a cornerstone of modern manufacturing, offering a perfect blend of precision engineering and cost-effective production. These components are created through a sophisticated process where molten aluminum is injected into reusable molds under high pressure, resulting in complex geometries with exceptional dimensional accuracy. The process enables the production of parts with thin walls, intricate details, and excellent surface finishes, while maintaining structural integrity. These parts are characterized by their outstanding strength-to-weight ratio, making them ideal for applications where weight reduction is crucial. The thermal conductivity of aluminum, combined with the precision of die casting, creates components that efficiently dissipate heat, crucial for automotive and electronic applications. Modern aluminum die casting parts incorporate advanced design features such as internal channels, mounting points, and integrated functionality, reducing the need for secondary operations. The versatility of these components extends across various industries, from automotive engine blocks and transmission housings to electronic enclosures and aerospace components. The process ensures consistent quality across large production runs, with each part maintaining exact specifications and mechanical properties.