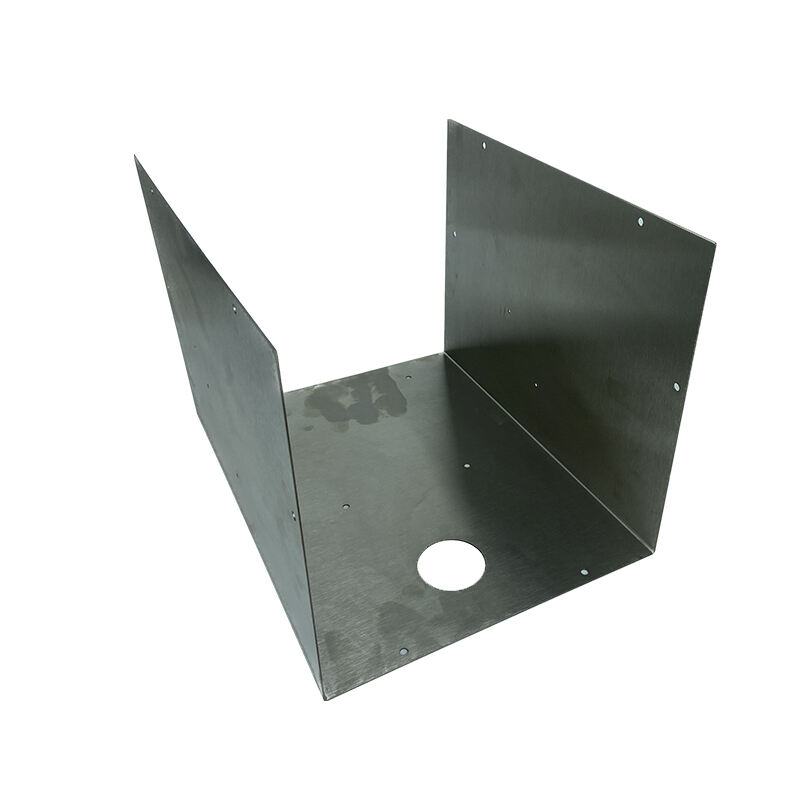

custom metal stamping

Custom metal stamping represents a sophisticated manufacturing process that transforms flat metal sheets into specific shapes through mechanical deformation. This versatile technique employs specialized tools and dies to create precise components for various industries. The process begins with raw metal sheets, which are fed into advanced stamping machines capable of performing multiple operations including blanking, piercing, forming, and drawing. Modern custom metal stamping incorporates computer-aided design (CAD) systems and precision-controlled equipment to ensure exceptional accuracy and repeatability. The technology allows for both simple and complex geometries, making it ideal for producing everything from basic brackets to intricate automotive components. The process can handle various materials including steel, aluminum, copper, and brass, with thickness ranges from thin gauge to several millimeters. Custom metal stamping excels in high-volume production scenarios, offering consistent quality while maintaining cost-effectiveness through automated processes and minimal material waste. The technique has evolved to include progressive die stamping, which enables multiple operations in a single press stroke, significantly improving production efficiency and reducing cycle times.