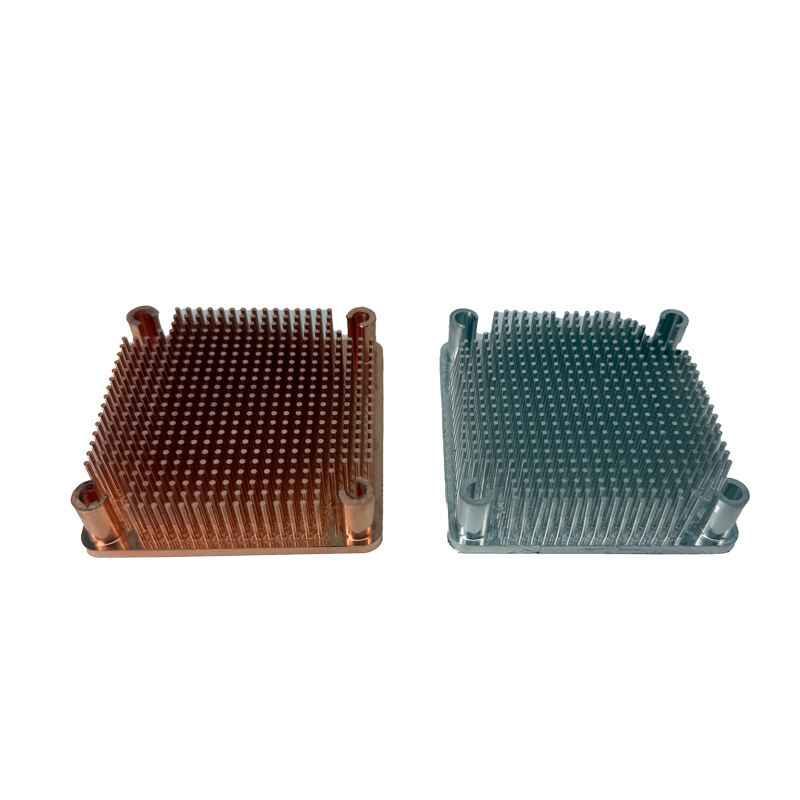

heatsink profile

A heatsink profile is an essential thermal management component designed to efficiently dissipate heat from electronic devices and systems. This precisely engineered structure consists of a base plate and multiple fins or pins that maximize surface area for optimal heat transfer. The profile is typically manufactured from highly conductive materials such as aluminum or copper, utilizing advanced extrusion or casting processes to achieve specific thermal performance requirements. The design incorporates sophisticated geometries that promote natural or forced convection, enabling effective heat removal from critical components. Modern heatsink profiles feature innovative fin arrangements, customizable dimensions, and various surface treatments to enhance thermal conductivity. These profiles serve crucial roles in maintaining operational temperatures within safe limits for processors, power supplies, LED lighting systems, and industrial equipment. The versatility of heatsink profiles allows for integration into diverse applications, from compact consumer electronics to large-scale industrial systems, while their modular nature facilitates easy installation and maintenance. Advanced computational fluid dynamics analysis guides the development of these profiles, ensuring optimal performance under various thermal loads and environmental conditions.