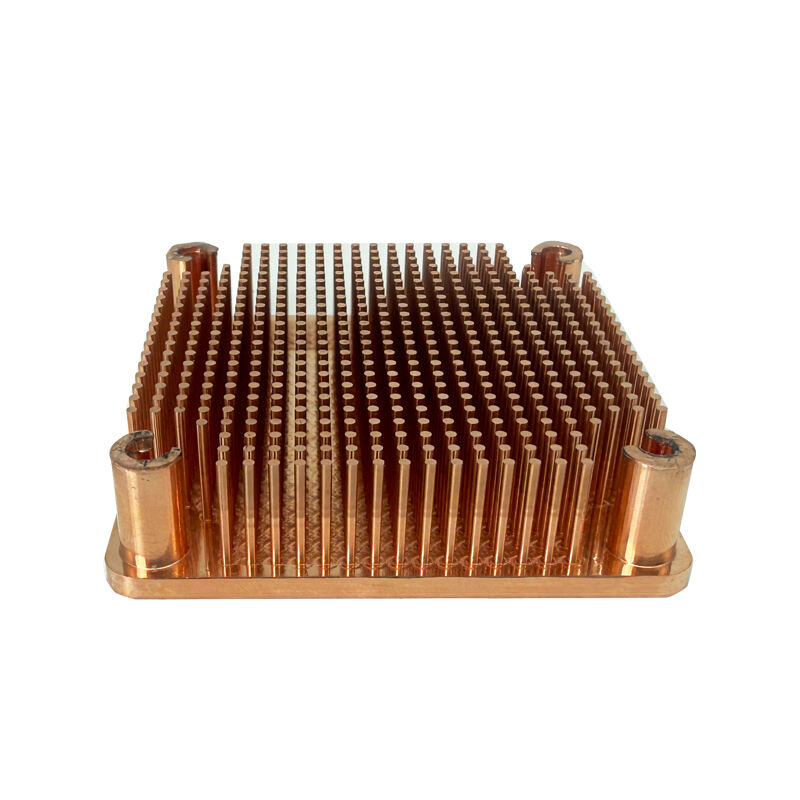

circular heat sink

The circular heat sink represents a cutting-edge thermal management solution designed to efficiently dissipate heat from electronic components and systems. This innovative cooling device features a radial design with concentric fins arranged in a circular pattern around a central core, maximizing the surface area available for heat transfer while minimizing space requirements. The unique circular configuration allows for omnidirectional airflow, creating a more efficient cooling pattern compared to traditional rectangular heat sinks. The device typically incorporates high-thermal-conductivity materials such as aluminum or copper, ensuring rapid heat transfer from the source to the surrounding environment. The circular design also promotes natural convection, as heated air rises uniformly through the fins, creating a chimney effect that enhances cooling performance. These heat sinks are engineered with precise fin spacing and thickness to optimize the balance between thermal performance and air resistance, resulting in improved cooling efficiency in both active and passive cooling applications. The versatility of circular heat sinks makes them ideal for various applications, including LED lighting systems, power electronics, computer processors, and industrial equipment where reliable thermal management is crucial for maintaining optimal performance and extending component lifespan.